|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

4-5. AXLE MAINTENANCE (cont)

a. Differential Carrier (cont).

ADJUSTMENTS (cont)

26

(cont)

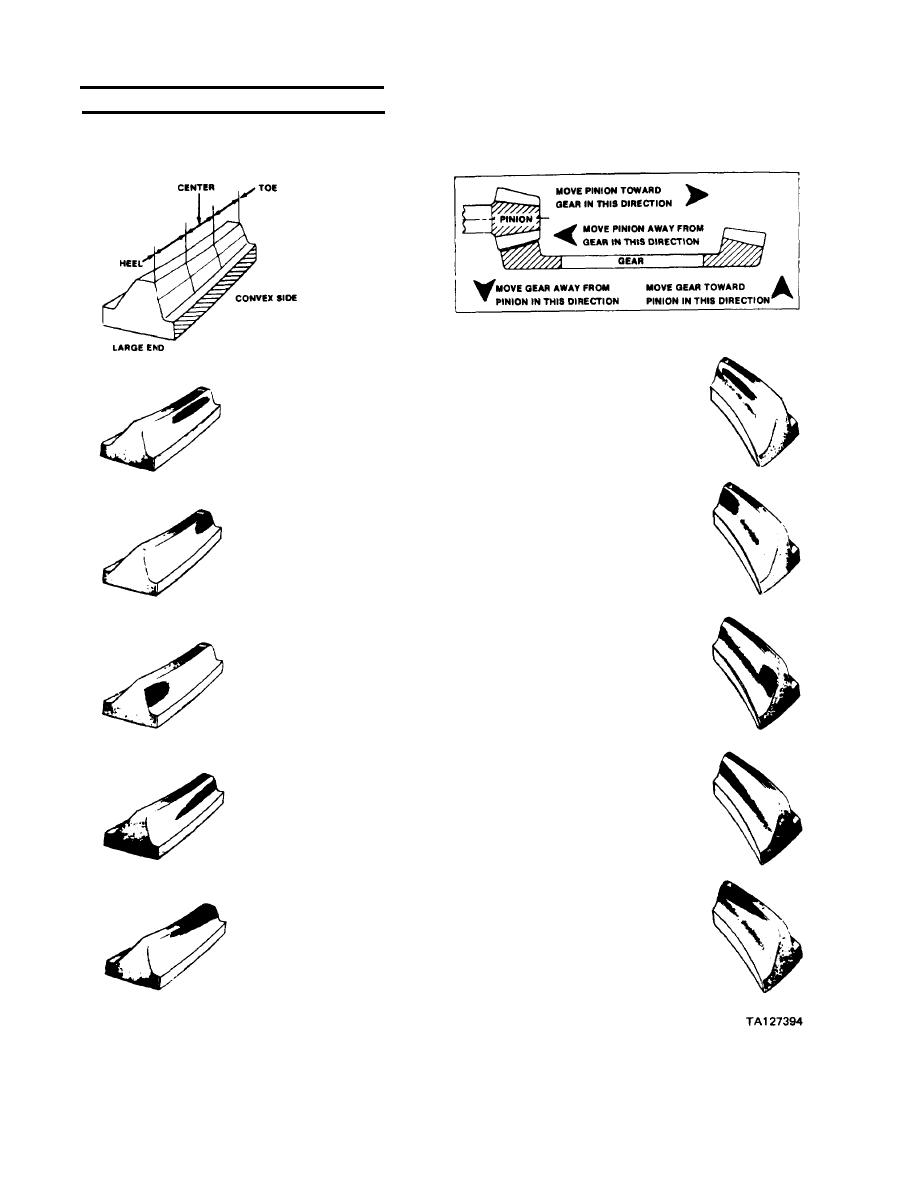

ALL CONTACT BEARINGS SHOWN BELOW ARE ON RIGHT HAND SPIRAL

RING GEAR THE DRIVE IS ON THE CONVEX SIDE OF THE TOOTH.

CONDITION 1

TYPICAL PREFERRED BEARING ON BOTH SIDES OF TOOTH

WHILE UNDER A LIGHT LOAD

CONDITION 2

TOE BEARING ON BOTH SIDES OF TOOTH-GEAR SET NOISY. TO

MOVE BEARING TOWARD HEEL INCREASE BACKLASH WITHIN LIMITS

BY MOVING GEAR AWAY FROM PINION.

CONDITION 3

HEEL BEARING ON BOTH SIDES OF TOOTH-GEAR SET NOISY AND

COULD RESULT IN EARLY GEAR FAILURE. TO MOVE BEARING TO-

WARD TOE DECREASE BACKLASH WITHIN LIMITS BY MOVING GEAR

TOWARD PINION.

CONDITION 4

LOW BEARING ON GEAR AND HIGH BEARING ON PINION. CORRECT

BY PULLING PINION AWAY FROM GEAR. INCREASE MOUNTING DIS-

TANCE BY ADDING SHIMS BETWEEN BEARING CAGE AND DIFFERENTIAL

HOUSING.

CONDITION 5

HIGH BEARING ON GEAR AND LOW BEARING ON PINION, CORRECT

BY MOVING PINION IN TOWARD GEAR. DECREASE MOUNTING DIS-

TANCE BY REMOVING SHIMS FROM BETWEEN BEARING CAGE AND

DIFFERENTIAL HOUSING.

BACKLASH

BACKLASH SHOULD BE MEASURED WITH A DIAL INDICATOR

RIGIDLY MOUNTED WITH THE STEM PERPENDICULAR TO THE TOOTH

SURFACE AT THE EXTREME HEEL.

4-246

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |