|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

4-3. FUEL SYSTEM MAINTENANCE (cont)

b. Fuel Injection Pump (cont).

STEP

ITEM

LOCATION

ACTION

REMARKS

REASSEMBLY (cont)

d. Install hydraulic head (81) in fixture on air inlet side of

(cont)

fixture

e. Rotate rotor until cam rollers (118) are pushed to their

extreme outward position by air pressure

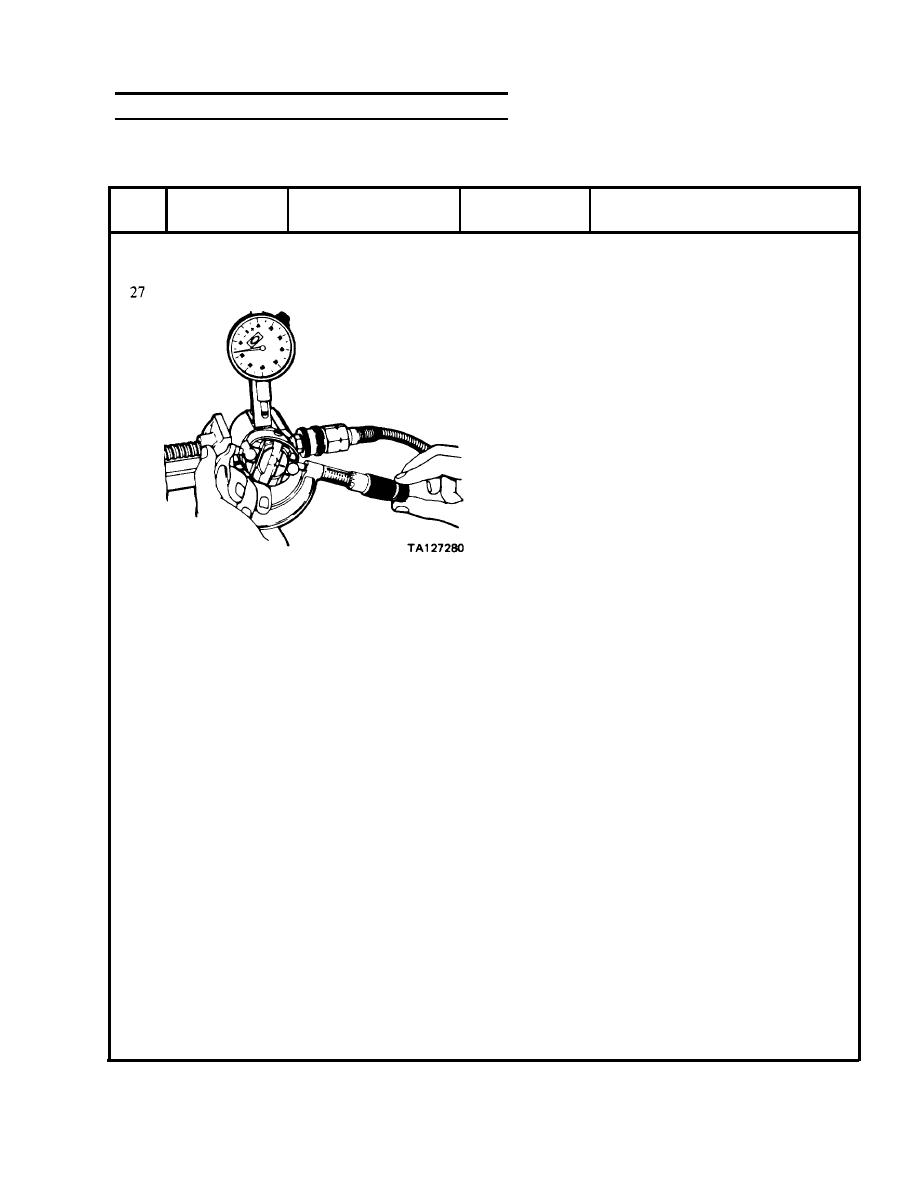

f. Use a two inch micrometer and measure cam roller-to-cam

roller dimension as shown

g. Dimension shall be 1.9650.0015 inch; if necessary, turn

adjusting screw (120) clockwise to decrease travel

h. Remove hydraulic head from fixture and install in fixture

P/N 19965

j. Cam ring (116)

Position

On hydraulic head with directional arrow

facing upward

k. Governor weight

Install

Align mark on governor weight retainer

retainer (115)

(1 15) with mark on rotor (123)

l. Retaining ring (114)

Install

Be sure ring is installed in its groove

m. Hydraulic head (81)

Invert in

Be sure governor weight retainer engages

holding

bar on holding fixture

fixture

NOTE

Delivery valves are supplied in standard size and oversize; size used

is etched on rotor.

n. Delivery valve (109)

Install

Be sure it operates freely in its bore

o. Spring (108)

Install

p. New stop (107)

Install

q. Delivery valve

Install

Relieved end facing down; use tool

screw (106)

P/N 13383 and tighten to 85-90 pounds

inch torque

r. Two rotor

Install

Lift hydraulic head up until inside face of

retainers (111)

head is flush with rotor end, then position

with outer sleeve of rotor retaining ring

installation tool P/N 13375

s. Snap ring (1 10)

Install

t. Liner (103)

Install

Install so that large slot is in line with head

locating screw hole and marking indicating

pump rotation is facing upward

4-117

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |