|

|||

|

|

|||

|

Page Title:

HYDRAULIC LIFT SYSTEM TROUBLESHOOTING |

|

||

| ||||||||||

|

|

TM 10-3930-638-24&P

3-29. HYDRAULIC LIFT SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

1. UNABLE TO LIFT A LOAD (ALL OTHER FUNCTIONS NORMAL) (cont)

Start engine and operate at idle speed.

Step 1.

NOTE

Increase engine speed as necessary in following

steps to prevent engine stall.

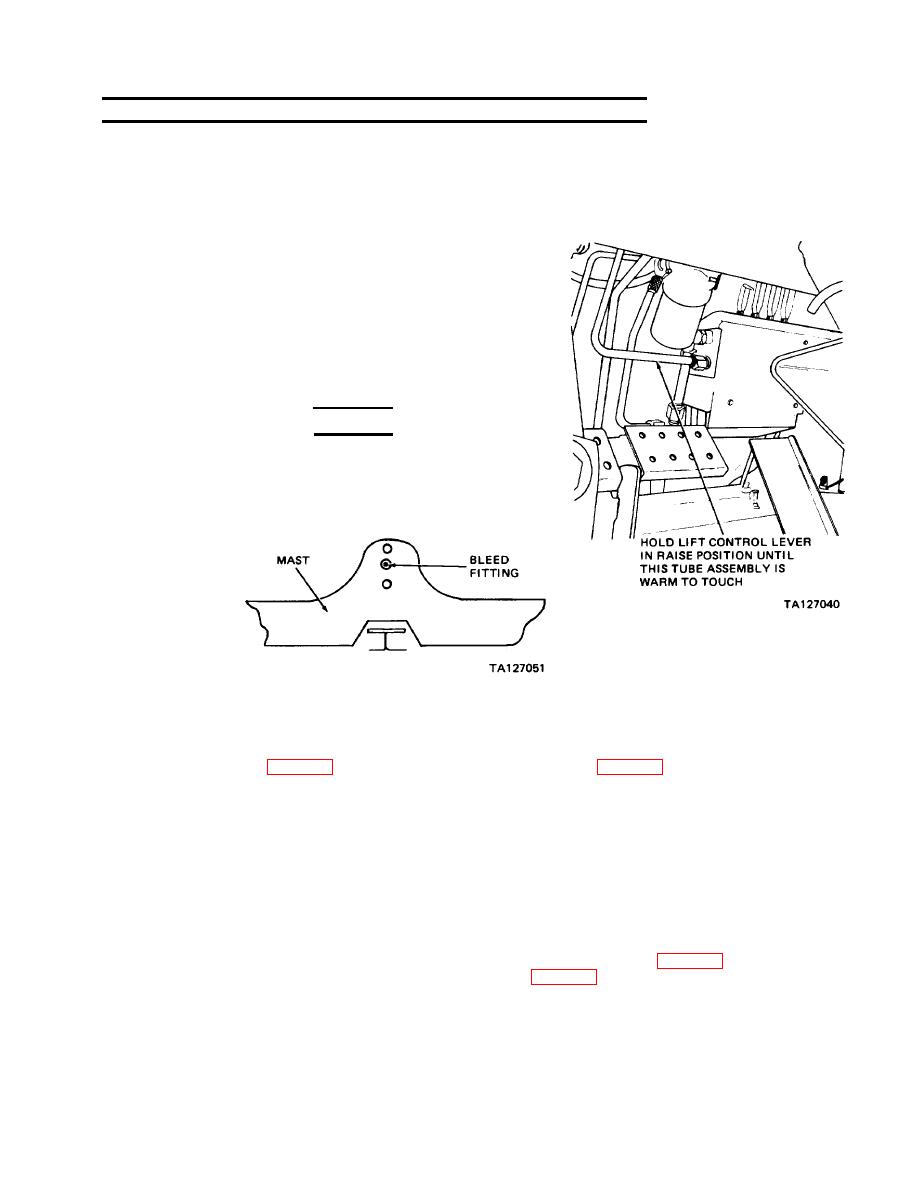

With no load on forks, place LIFT control lever in

RAISE position until tube assembly shown is warm

to touch (mast assembly will be at full height).

WARNING

Don't look directly down at fitting when per-

forming following steps; hydraulic oil is under

pressure. Serious injury may result.

Loosen bleed fitting at top of lift cylinder assembly.

While an assistant places LIFT control lever in RAISE position, observe fitting at top of lift cylinder

assembly for hydraulic oil leakage. (Slight weeping of oil is permissible.)

a. If hydraulic oil leakage (other than slight weeping) is observed, remove lift cylinder assembly

b. If hydraulic oil leakage is not observed, tighten bleed fitting and proceed to step 2.

With engine operating at idle speed and LIFT control lever in RAISE position (mast assembly will be

Step 2.

at full height), check for hydraulic oil leakage at end cap assembly (located at top of lift cylinder

assembly) and at gland assembly (located at top of lift cylinder body).

NOTE

Increase engine speed as necessary to prevent engine stall.

a. If hydraulic oil leakage is observed, remove lift cylinder assembly (para 3-30e), and repair or

replace gland assembly or end cap assembly (para 3-30e).

b. If hydraulic oil leakage is not observed, proceed to step 3.

3-195

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |