|

|||

|

|

|||

|

Page Title:

ENGINE DOES NOT DEVELOP FULL POWER OR SPEED |

|

||

| ||||||||||

|

|

TM 10-3930-636-24&P

3-4. FUEL SYSTEM TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

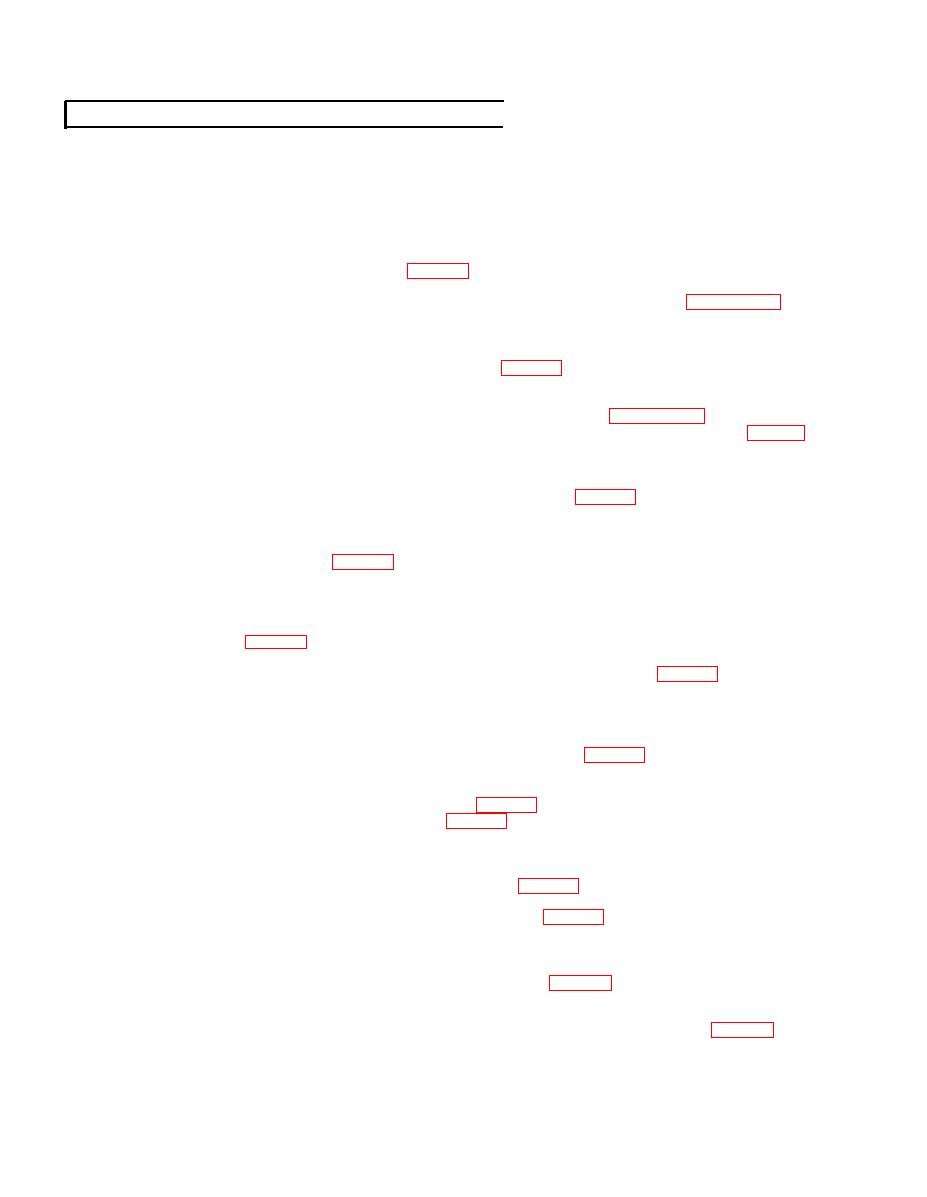

7. ENGINE DOES NOT DEVELOP FULL POWER OR SPEED (cont)

Step 5. Check fuel injection pump timing (para 3-5a(3)).

a. If fuel injection pump timing is not correct, adjust timing as described in paragraph 3-5a(3).

b. If fuel injection pump timing is okay, proceed to step 6.

Step 6. Disconnect and remove fuel injector return lines (para 3-6a).

Check return lines for clogged condition.

a. If fuel injector return lines are clogged, clean as described in paragraph 3-6a. After cleaning

return lines, recheck to ensure that all foreign matter has been removed, then reinstall (para 3-6a).

b. If fuel injector return lines are not clogged, proceed to step 7.

Step 7. Disconnect fuel lines from fuel injection pump at fuel injectors (para 3-6a) one at a time, crank engine

and check that fuel is pumped out of disconnected fuel line.

a. If fuel is not pumped out of disconnected fuel line when engine is cranked, replace associated

connector screw (para 4-3b; notify general support maintenance).

b. If fuel is pumped out of disconnected fuel line, proceed to step 8.

Step 8. Disassemble fuel injection pump and check governor parts and linkage for wear, sticking condition, or

binding (para 4-3b; notify general support maintenance).

a. If governor parts and linkage are worn, sticking, or binding replace (para 4-3b).

b. If governor parts and linkage are okay, proceed to step 9.

Step 9. Disassemble fuel injection pump and check governor linkage and metering valve for binding, foreign

matter and burrs; check metering valve for sticking condition (para 4-3b, notify general support

maintenance).

a. If linkage is binding or burred, replace (para 4-3b); if foreign matter is present, remove; if

metering valve is sticking, replace (para 4-3b).

b. If linkage and metering valve check okay, proceed to step 10.

Step 10. Check governor linkage hook for proper adjustment (para 4-3b; notify general support maintenance).

a. If governor hook is not properly adjusted, adjust (para 4-3b).

b. If governor hook is properly adjusted, proceed to step 11.

Step 11. Disassemble automatic advance components and inspect (para 4-3b; notify general support

maintenance).

a. If automatic advance components are worn or damaged, replace and adjust (para 4-3b).

b. If automatic advance components are okay, proceed to step 12.

3-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |