|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-638-24&P

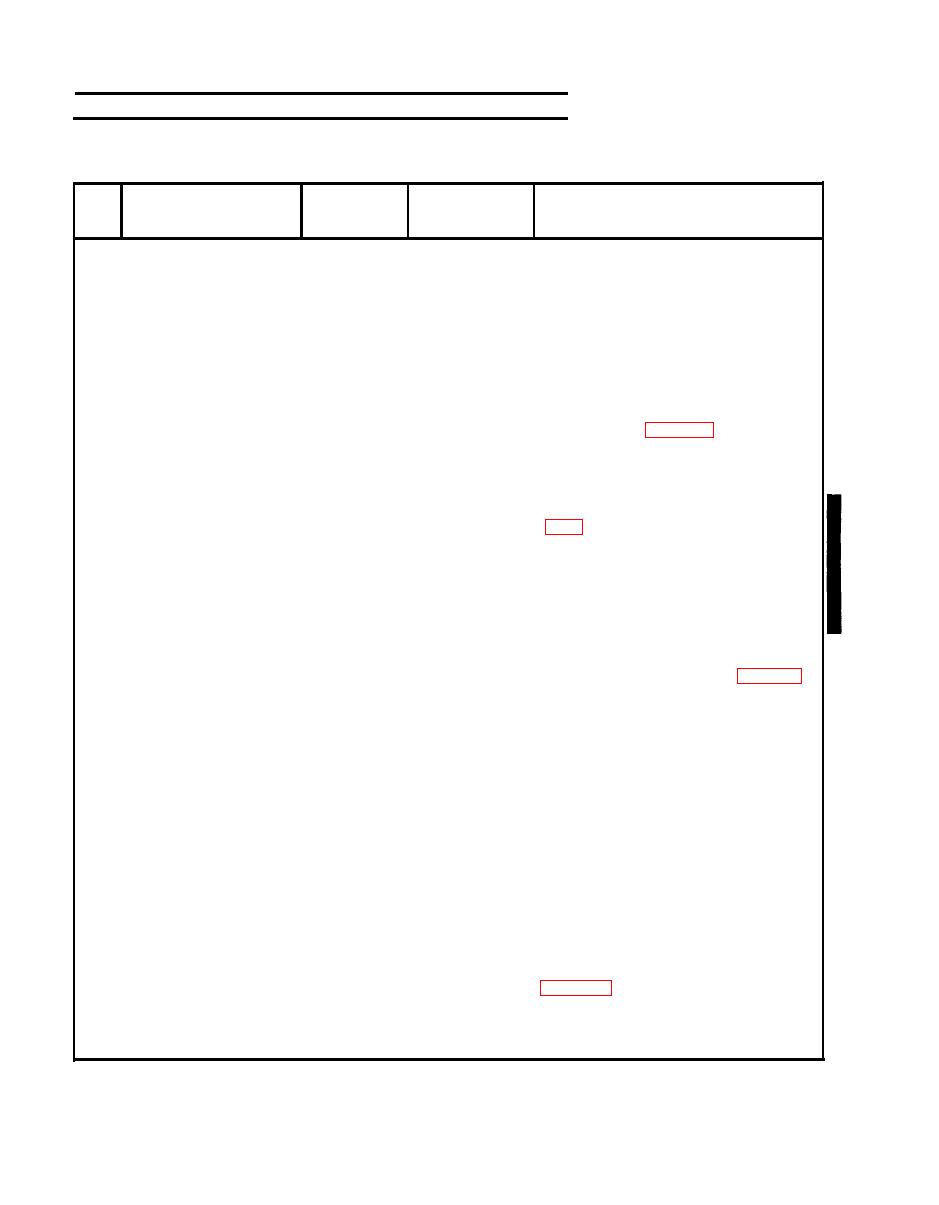

2-56. HYDRAULIC LIFT SYSTEM MAINTENANCE (cont)

a. Operational Test (cont)q

IF INDICATION

IF INDICATION

NORMAL

PROCEDURE/ACTION

STEP

IS ABNORMAL

IS NORMAL

INDICATION

Proceed to step 5

Proceed to step 8

7

Place tilt control lever in

Mast moves

rearward

REAR position; release

when mast is in full rear-

smoothly

ward position

8 Place tilt control lever in

FWD position; release

lever when mast is in

vertical position

Proceed to step 10 Replace restrictor (para 2-56f(1))

Place lift control lever in

Mast moves

9

downward

LOWER position; release

smoothly

when forks are touching

ground

Downward drift Proceed to step 11 Bleed air from lift cylinder assembly (para

Position vehicle to pickup

10

of mast shall not

a 4000 pound load, Place

lift control lever in

exceed one inch.

RAISE position; release

when mast is at full

height, Allow mast to

remain at full height

for two minutes

Proceed to step 14 Check sideshift chains and pulleys for wear

Place lift control lever in

Forks shift

11

or damage; replace as necessary (para 2-56e).

load to right

LOWER position; release

Proceed to step 12

smoothly

lever when forks are

three feet from ground,

Then place shift control

lever in RIGHT position

until forks are at ex.

treme right position

Notify direct support maintenance (sideshift

Place lift control lever in

Reconnect fitting

No oil leakage

12

to sideshift cyl-

cylinder requires replacement)

at sideshift

LOWER position until

inder assembly.

load is resting on ground.

cylinder

Proceed to step

Disconnect fitting at rod

assembly port

end of sideshift cylinder

where fitting

13

assembly and plug fitting.

disconnected

Place shift control lever

in RIGHT position and

hold

Notify direct sup- Tighten fittings; replace leaking hoses

No oil leaks

13

Check hoses, lines and

fittings between control

port maintenance (para 2-56f)

(control valve

valve and sideshift cylinder

requires replace-

assembly for oil leaks

ment)

2-394 Change 2

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |