|

|||

|

|

|||

|

Page Title:

ENGINE STALLS FREQUENTLY OR DOES NOT DEVELOP FULL POWER (cont) |

|

||

| ||||||||||

|

|

TM 10-3930-638-24&P

1 2 - 9 . ENGINE TROUBLESHOOTING (cont)

MALFUNCTION

TEST OR INSPECTION

CORRECTIVE ACTION

5. ENGINE STALLS FREQUENTLY OR DOES NOT DEVELOP FULL POWER (cont)

Step 7.

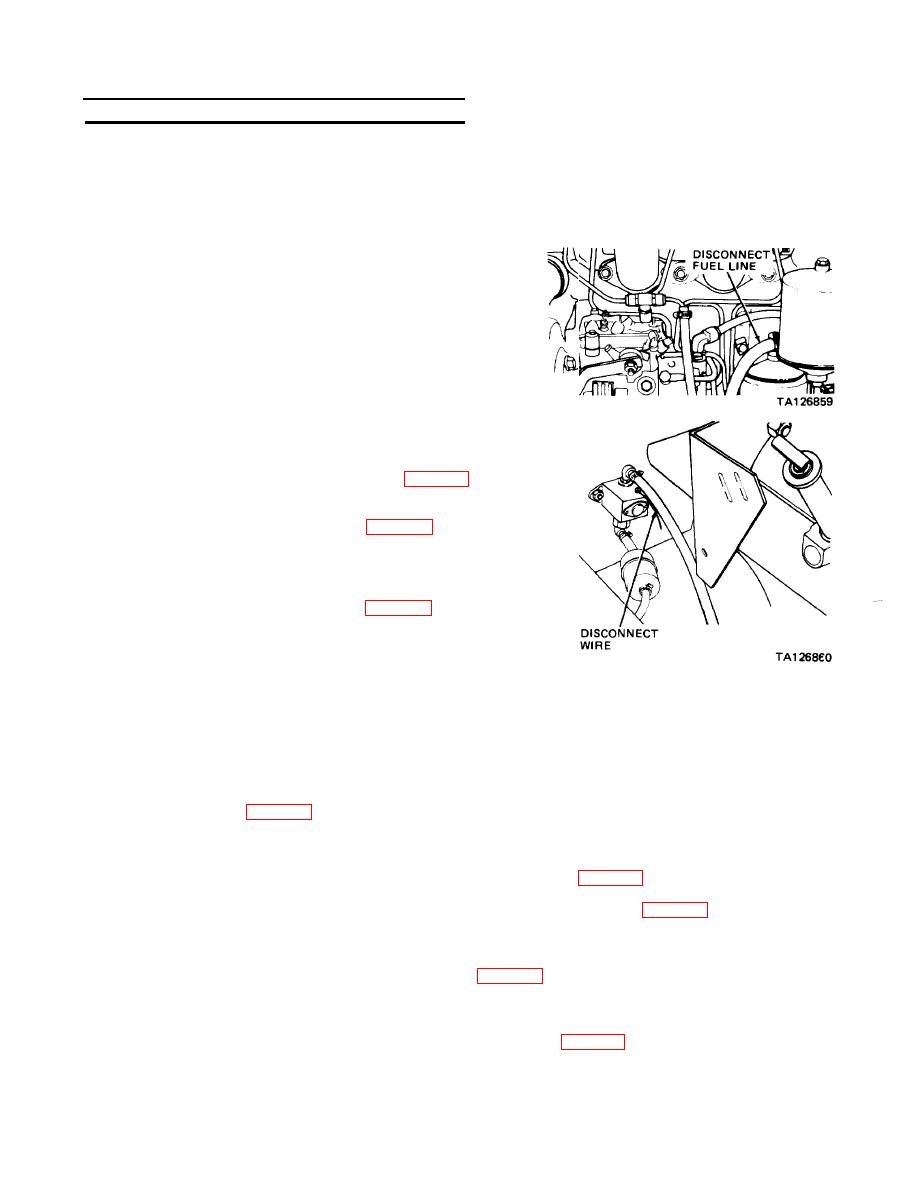

Disconnect fuel line at fuel filter head.

Place ignition switch in ON position and check if a

slight buzz can be heard at electric fuel pump and if

fuel is pumped out of disconnected line.

a. If slight buzz indicating electric fuel pump operation

is not heard, disconnect wire at terminal on electric

fuel pump and check for +24 Vdc between wire and

chassis ground.

(1) If +24 Vdc is not obtained, troubleshoot

electrical system (para 2-19).

(2) If +24 Vdc is obtained, replace electric

fuel pump (para 2-15b).

b. If fuel is not pumped out of disconnected fuel line,

remove lines and fittings between fuel tank and fuel

filter head and clean/replace lines, in-line fuel filter,

and/or fuel strainer (para 2-1 5).

c. If fuel is pumped out of line, reconnect line and

proceed to step 8.

Step 8.

Operate engine for 15 minutes at idle speed.

Carefully and slowly remove radiator cap.

Check coolant temperature using a thermometer; be sure thermometer does not touch any metal

parts of radiator.

Coolant temperature shall be between 175 to 200 degrees F.

a. If coolant temperature is not between 175 to 200 degrees, remove and test thermostat

b. If coolant temperature is between 175 to 200 degrees F, proceed to step 9 below.

Check for correct adjustment of accelerator/throttle control (para 2-15i).

Step 9.

a. If adjustment of accelerator/throttle control is not correct, adjust (para 2-15i).

b. If accelerator/throttle control adjustment is okay, proceed to step 10 below.

Step 10. Remove drive belt from engine water pump (para 2-17f).

Start engine and operate at idle speed for five minutes maximum.

Check if engine power increases.

If engine power increases, replace water pump assembly (para 2-17e) and reinstall drive belt on

water pump.

2-20

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |