|

|||

|

|

|||

|

Page Title:

Section V. REPAIR OF WHEEL ASSEMBLIES |

|

||

| ||||||||||

|

|

ME 3930-624-34/4-22

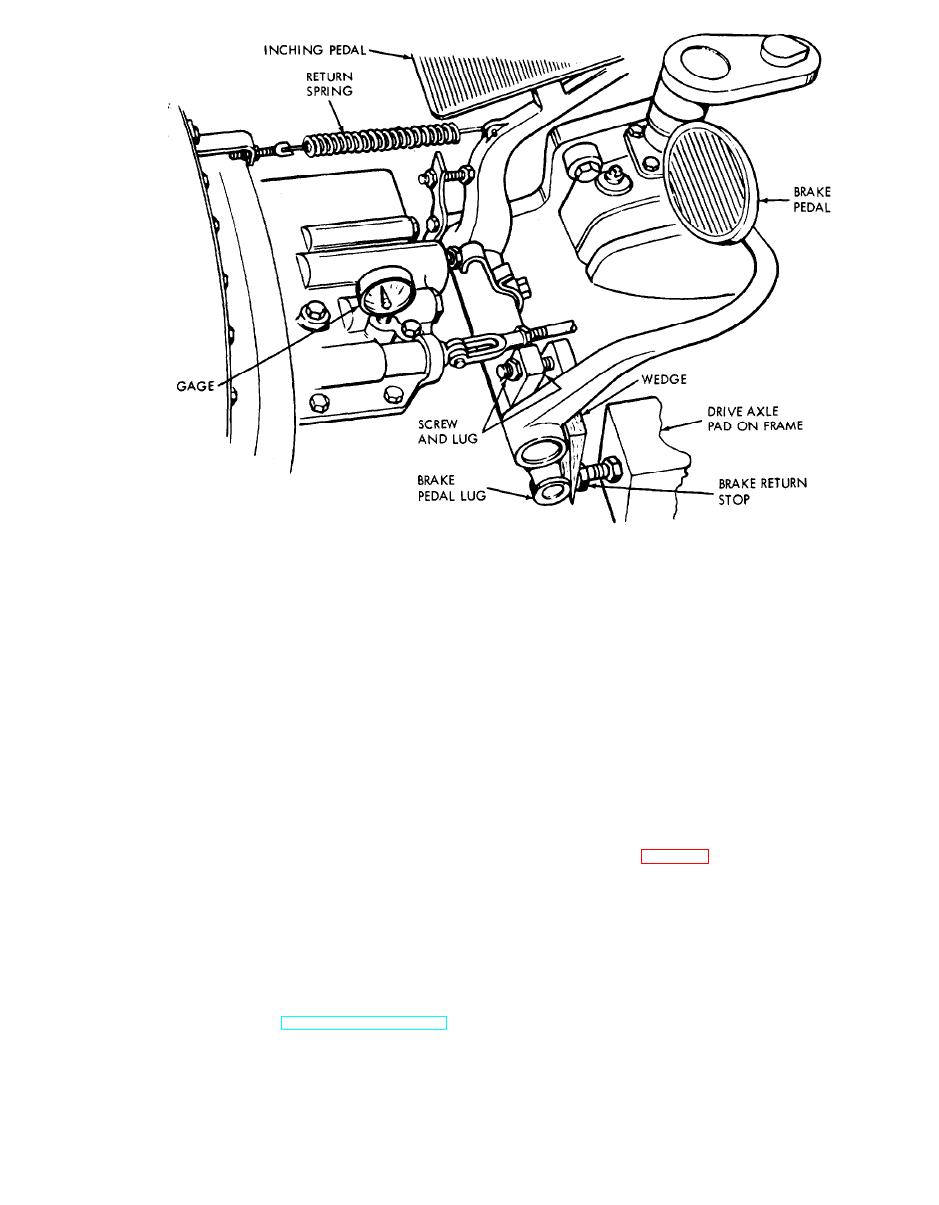

Figure 4-22. Inching pedal hydraulic adjustment.

(f) Set the adjusting screw to contact the

forward and ensure that the pressure reading does

brake pedal lug and lock.

not increase. Shut down the engine.

(g) Operate the engine at high idle speed.

(h) Loosen the inching spring mounting

Remove the wedge and compress the inching pedal

capscrew and readjust the spring to a 3/32-1/8

spring to 3/32- 1/8 in. Pressure gage should

in. deflection. Tighten the capscrew. Check for free

indicate 100-160 psi. Pull the inching pedal

oscillation of the inching spring.

Section V. REPAIR OF WHEEL ASSEMBLIES

4-14. General

Note. Figure 4-23 is an illustration of the drive wheel.

The drive wheel assembly consists of a wheel, a tire,

The steer wheel is similar, with differences noted.

a bull gear and bearings. The bull gear is bolted

inside the wheel. Part of the space on the inside

(1) Remove capscrew (1), lockwasher (2), and

surface of the wheel serves as a brake drum. The

hub cap (3).

steer wheel assembly consists of a wheel, a tire and

(2) Remove cotter pin (4), bearing adjusting

nut (5), washer (6), and outer bearing (7).

4-15. Wheel Repair

a. Removal. Refer to TM 10-3930-624-12 for

the wheel removal procedure.

4-25

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |