|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

indicator up and down in cylinder and note largest and

(2) Tappet travels 0.002 to 0.006 inch,

smallest indications. The difference between indications

through rotator clearance, lifting keys from valve stem

is the amount of taper of the cylinder. If out of round or

contact, but not yet lifting valve. Valve can turn now, as

taper exceeds 0.004 inch or if overall wear exceeds

keys no longer grip it at stem.

0.008 inch, rebore cylinder walls and install oversize

(3) Continued lift of tappet raises valve

pistons and rings.

through push on cap. Valve will rotate slightly each time

(11) Compare' cylinder bore measurements

it opens, due to various forces acting on it.

with diameter when new and determine whether to

b. Removal.

rebore to 0.020 or 0.040 inch oversize.

(1) Remove cylinder head, manifold, and

(12) Rebore all cylinders with cylinder boring

valve covers.

equipment to same predetermined oversize.

Plug oil return holes in block with rags, to prevent

dropping parts into oil pan.

(2) With

conventional

valve

spring

NOTE

compressor, raise spring retainer and valve spring

enough to remove cap and two keys. With these parts

Engine will now need pistons and

removed, lift valve from engine block, and place in

rings in oversize corresponding to

numbered valve rack so each valve can be identified,

new cylinder bore diameter.

and returned to the same port from which it came. Keep

components from each valve together to reduce the

(13) When cylinder bores have been finished to

amount of adjusting at reinstallation.

size, coat walls with OE to: prevent rusting.

c. Inspection.

(1) Inspect valve for burning at the neck,

6-83.

VALVES.

below head of valve, carbon formation on head or stem,

or pitting of stem or face of valve.

a. Description. The engine valves are equipped

(2) Inspect valve seat in block for burning or

with valve rotators, which consist of a special seat

uneven seating of valve. Inspect valve guide for wear or

retainer (Figure 6-40), a cap, a pair of flat half-round keys,

gumming from carbon deposits.

and a special shaped valve stem. The lift cycle of the

d. Repair.

valve is as follows:

(1) Original valves in this engine are not to be

(1) Tappet travels through normal valve

serviced for any reason. If they are found to be

clearance to contact cap.

unserviceable, replace. with new valves.

(2) Service replacement:

valves with

conventional valve grinding techniques.

Grind

replacement valve faces to 45 deg. angle, with 1/16 inch

margin, on standard shop valve grinder, and reface valve

seats to same angle.

(3) Replace exhaust valve seat inserts which

are beyond practical repair, using standard procedure of

pulling old insert and driving in a new insert which has

been chilled in dry ice for twenty minutes.

(4) Replace valve guides worn beyond 0.0025

clearance as follows: (a) Run tappet adjusting screws all

the way down and turn engine so tappet is off cam lobe.

(b) Drive out guides with 1/2 inch diameter

drift, with 5/16 inch diameter pilot. Drive in new guides

with same pilot to same depth as old guides.

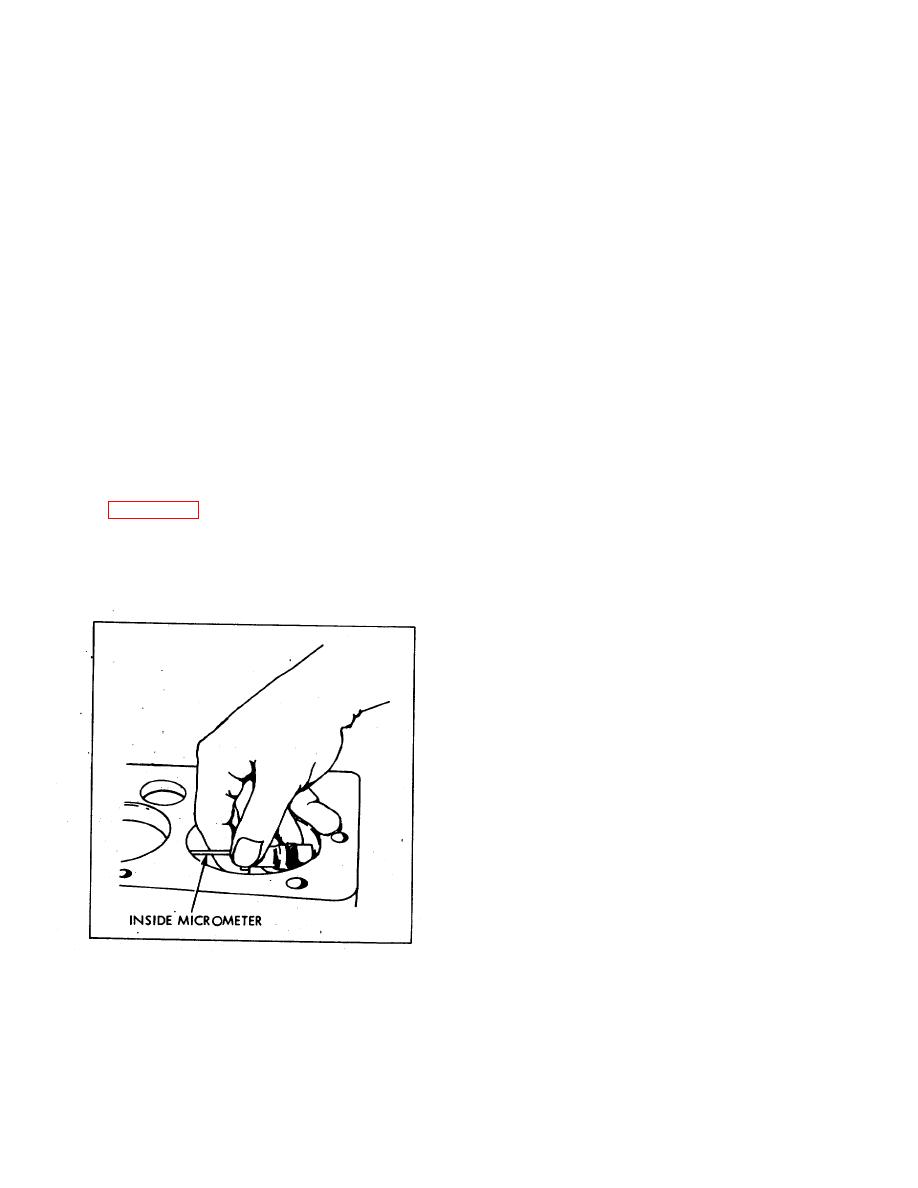

Figure 6-39. Measuring Cylinder Bore

111

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |