|

|||

|

|

|||

|

Page Title:

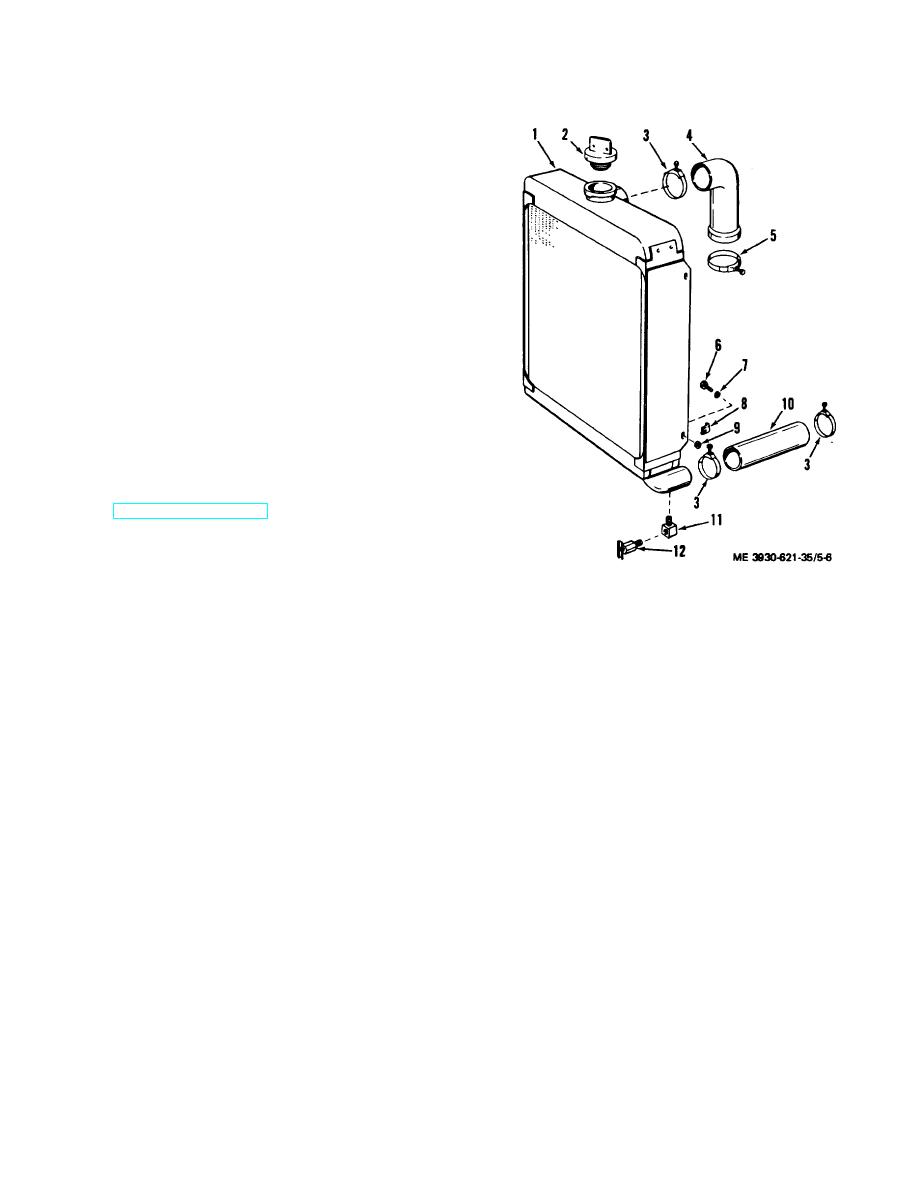

Figure 5-6. Radiator and connections exploded view |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

(1) Dry radiator core thoroughly. Water in the core

will prevent air from passing out a small leak.

(2) Completely immerse radiator in water.

(3) Apply no more than 10 psi of compressed air and

note any air leakage.

(4) Repair any leaks by soldering.

b. Test for clogging as follows:

(1) Check core tube inlet passages for obstructions.

(2) Fill radiator with water and seal upper water

passages.

(3) Inspect for a steady and full stream of water

flowing out of lower passage. If stream is small or

erratic, the core tubes are restricted or plugged.

(4) A plugged radiator must be boiled out.

c. Straighten any bent cooling fins, being careful not to

puncture tubes.

d. Test pressure caps for leaks and replace if faulty.

e. Check hoses for cracks or deterioration and

replace as authorized.

f. Check tank for damage. If damage cannot be

repaired by brazing, replace radiator and ac- cessories

as authorized.

5-19. Installation

Refer to TM 10-3930-621-12

for radiator installation

procedures.

1.

Radiator

7. Flat washer

2.

Pressure cap

8. Spacer

3.

Hose clamp

9. Nut

4.

Hose

10. Lower hose

5.

Hose clamp

11. Elbow

6.

Cap screw

12. Drain cock

Figure 5-6. Radiator and connections exploded view

5-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |