|

|||

|

|

|||

|

Page Title:

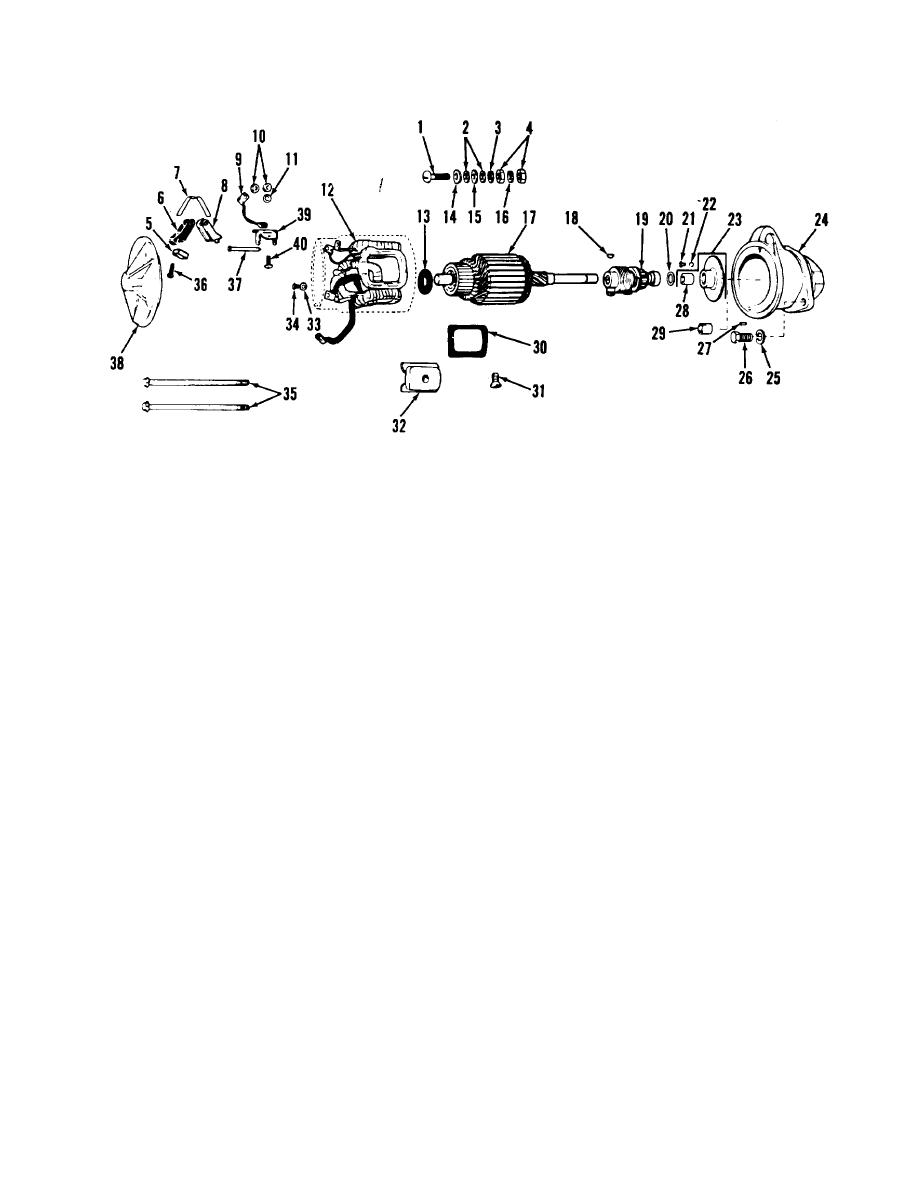

Figure 5-5. Starter, exploded view |

|

||

| ||||||||||

|

|

TM 10-3930-621-34

1. Stud

15.

Lock washer

28.

Center bushing

2. Flat washer

16.

Terminal bushing

29.

Drive bushing

3. Flat washer

17.

Armature

30.

Insulator

4. Nut

18.

Key

31.

Screw

5. Brush

19.

Drive assembly

32.

Pole

6. Brush holder

20.

Thrust washer

33.

Lock washer

7. Brush spring

21.

Screw

34.

Screw

8. Brush holder

22.

Lock washer

35.

Thru-bolt

9. Lead

23.

Center bearing

36.

Screw

10. Nut

24.

Housing

37.

Support

11. Lock washer

25.

Lock washer

38.

Frame

12. Fieldwinding

26.

Cap screw

39.

Support

13. Washer

27.

Pin

40.

Screw

14. Flat washer

Figure 5-5. Starter, exploded view

d.

Carefully inspect armature commutator.

If

5-12. Inspection and Repair

burned, rough or out-of-round, turn down as follows:

a. Clean starter motor parts with cleaning

(1) Place armature in lathe and turn down

compound, solvent (Spec. P-S-661). Do not use

commutator until true. Make certain cut is not made on

cleaning solvents on drive mechanism or armature and

commutator riser bars as solder will be removed, thus

field coils. Dry parts with compressed air.

weakening coil connections at this section. Remain

b.

Check bushings for roughness, scoring or

approximately 3/16" from riser bars. Remove no more

excessive clearance. Bushing running clearances are as

than 0.03 of an inch from the face of the commutator.

follows: commutator end frame 0.0013" - 0.0090", center

(2) Check armature on a growler for shorts. Refer

bushing and drive housing bushing 0.0015" -0.0050"

to 5-13a

c. Check brush holders to be sure they will properly

hold brushes against commutator. Check spring tension

which should be 35 ounces. Check condition of brushes;

if

pitted

or

worn,

replace.

5-6

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |