|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

TM 10-3930-621-34

turned in a lathe to 0.002 inch maximum indicator

readings. Remove just enough material to make the

rings smooth and round. Polish with 400 grain or finer

polishing cloth and blow away all dust.

d. Bearing.

(1) The drive end frame bearing (28) can be

removed by detaching the retainer plate screws and then

pressing the bearing from the end frame. Check the

bearing and if it is in satisfactory con- dition, it can be

reused. Lubricate bearing. It should be filled 1/4 full

before reassembly.

Caution : Do not overfill or bearing will

overheat.

(2) If a new bearing is required, press it in with a

tube or collar that just fits over the outer race. If the felt

seal is worn excessively or hardened, it is recommended

that a new retainer plate be installed.

(3) The slip ring end frame bearing (24) should be

replaced if its grease supply is exhausted. Never attempt

to relubricate and reuse the bearing. Press the bearing

out from the slip ring end frame with a tube or collar that

fits inside the end frame housing. Press the bearing out

from outside the housing toward the inside. Press in the

new bearing with a flat plate. Press in from outside the

end frame until the bearing is flush with the outside of the

end frame. To prevent breakage of the end frame,

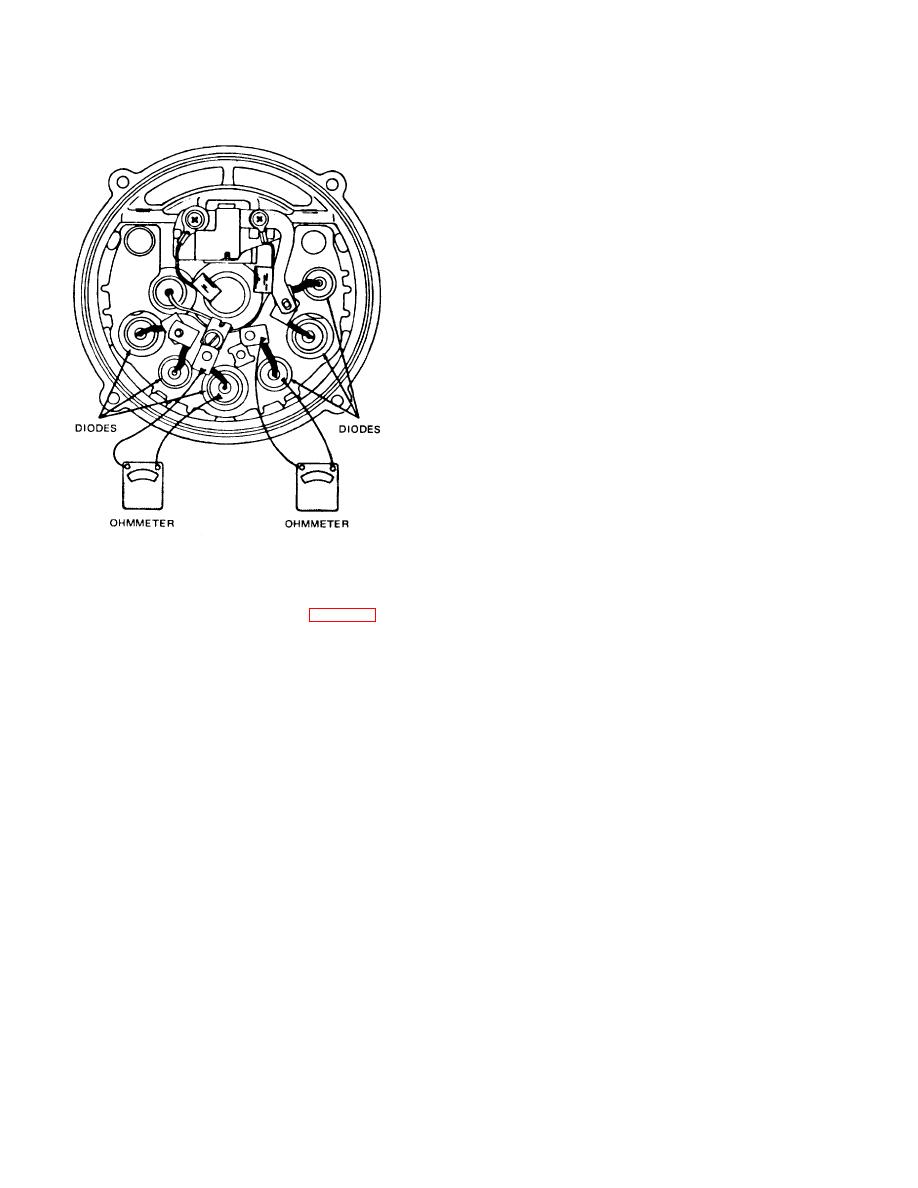

Figure 5-4. Diode testing.

support it on the inside with a hollow cylinder. When

b. Test rotor first, if not defective, then proceed to

installing the new bearing, use extreme care to avoid

the stator and then finally the diodes.

misalignment or other undue stress on the bearing.

5-5. Repair

Saturate the felt seal with engine oil (OE 20), then

a. Reference Items. Refer to figure 5-1 for items

reassemble the felt seal

referenced.

and steel retainer.

b. Semiconductor Device, Diode.

e. Brush.

(1) Support slip ring end frame (2) or heat sink (5)

(1) When separating the slip ring end frame from

and push out old diodes (16 and 22) with an arbor press

the rotor and drive end frame assembly, the brushes will

or vice.

drop down onto the shaft and come into contact with the

(2) Press in new diode with a special tool which fits

lubricant. If brushes are to be reused, they must be

over the outer edge of the diode while supporting the

thoroughly cleaned with a soft dry cloth. Brushes are

heat sink or slip ring end frame.

0.500 of an inch in length new and must be replaced

Caution: Do not hammer diodes into position

when 0.375 of an inch in length. Also, clean the shaft

as the shock will damage them.

thoroughly before beginning reassembly.

c. Slip Ring.

(2) Inspect the brush springs for evidence of any

(1) To clean dirty slip rings, use 400 grain or finer

damage or corrosion. Be sure to replace the brush

polishing cloth. Spin the rotor in a lathe or by other

springs if there is any doubt as to their condition. Use a

means and hold the polishing cloth against the slip rings

spring scale and check spring tension, which should be

until they are clean.

8-12 ounces. Replace spring if tension is less than 8

Caution: The rotor must be rotated so the slip

ounces.

rings will be cleaned evenly. Trying to clean the slip

(3) When new brushes are required, install them

rings by hand without spinning the rotor could result

as follows:

in flat spots on the slip rings, resulting in brush

(a) Remove two brush holder screws and brush

noise.

holder assembly from slip ring end frame.

(2) Out of round or rough slip rings should be

(b) After installing springs and brushes in brush

holder, insert a piece of straight wire or a pin

5-4

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |