|

|||

|

|

|||

|

Page Title:

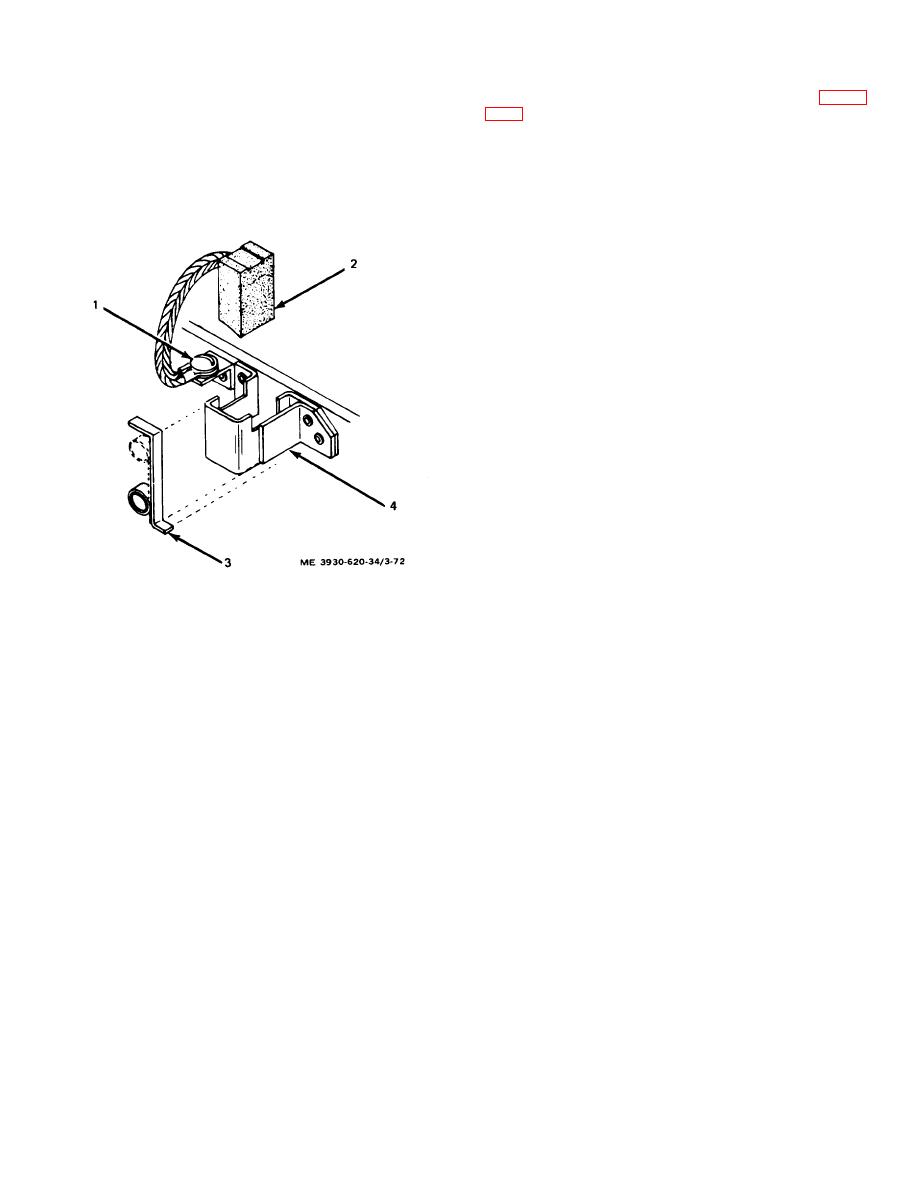

Figure 3-72. Power steering pump motor, brush location. |

|

||

| ||||||||||

|

|

e. Disassembly and Reassembly. If it is necessary

according to subparagraph c, above, and for grooves,

pits, and other signs of extreme wear.

to disassemble the motor, follow the sequence of figure

(4) Replace brush when brush shunt is 1/ 16

inch from slot in brush holder. Check that the brushes

move freely in the holder assembly.

(5) Check that brush spring tension is 30

ounces 20%

(6) Reassemble the brush, spring, and screw,

making sure the screw connection is clean and tight.

1. Retaining screw (2)

2. Brush (2)

3. Brush (2)

4. Brush holder assembly

Figure 3-72. Power steering pump motor, brush location.

3-83

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |