|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

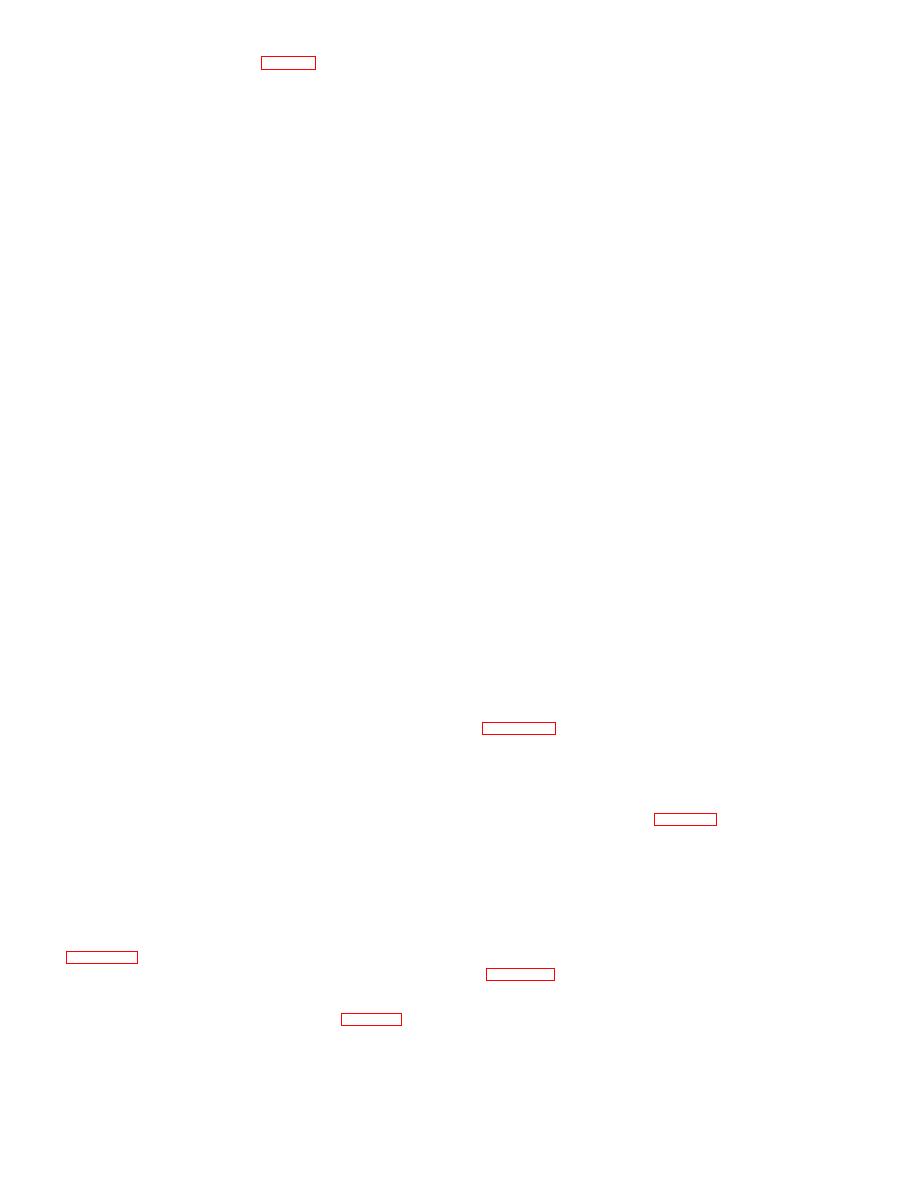

KEY to fig 3-19:

38.

Scre%w

1. Screw

39.

Flexible lead

2. Washer

40.

Marker.B2-

3. Nut

41.

Diode

4. Lead

42.

Marker A2

5. Screw

43.

Diode

6. Washer

44.

Nut (2)

a. Nut

45.

Lock washer (2)

8. Lead

46.

Screw (2)

9. Cable nipple

47.

Diode

10. Lead

48.

Flexible lead

11. Screw

49.

Marker.A1

12. Washer

50.

Screw (3)

13. Nut

51.

Lock washer (3)

14. Lead

52.

Diode support

15. Screw

53.

Marker, B2+

16. Washer

54.

Link, short (2)

17. Nut

55.

Link, long (4)

18. Lead

56.

Clamp

19. Screw

57.

Weather strip

Capacitor, 1000 F (2)

20. Washer

58.

Capacitor, 5500 F (2)

21. Nut

59.

22. Lead

60.

Screw (2)

23. Screw

61.

Lock washer (2)

24. Washer

62.

Screw 131

25. Nut

63.

Lock washer (3)

26. Lead

64.

Standoff insulator (3)

27. Nut

65.

Label

28. Lock washer

66.

Base assembly

29. Washer (2)

67.

Nut (2)

30. Screw

68.

Lock washer (2)

31. Nut

69.

Screw (2)

32. Lock washer

70.

Resistor assembly

33. Washer (2 )

71.

Nut (2)

34. Screw

72.

Lock washer (2)

35. Nut

73.

Screw (2)

36. Lock washer

74.

Resistor assembly

37 Washer (2)

(7) Measure D3 backward resistance by reversing

(2) Check capacitors for cracks and electrolyte

the connections. Backward-to-forward resistance ratio should

leakage.

be at least 10 to 1.

(3) Check wire leads for continuity using ohmmeter.

f. Reassembly. Reassemble in the reverse order of

(8) Test the capacitors as follows:

(a) Connect the positive ohmmeter lead to

metal clamp (561.

terminal B2+.

(b) Touch the negative ohmmeter lead to the

Note. Silicone grease must be applied to

left-most capacitor terminals, and then to the right-most

the mating surfaces between the diode

terminals.

support (52) and diodes l, D2, and D3.

(c) In each case, the meter pointer should

g. Installation. Install the capacitor and diode assembly

swing toward zero and then rise.

using the two screws (60, fig. 3-19) and lock washer (61).

(9) Reconnect the D3 lead to the capacitor

Reconnect leads.

connection.

3-11. Protective Circuit

c. Removal.

a. Test.

(1) Tag and disconnect all leads coming to terminals

(1) Use cardboard to insulate all forward and reverse

Al, A2, B2-, and B2+.

contacts in the contactor unit (except EC contactor).

(2) Remove the two screws (60) and lock washers

Note.

Seat must be depressed and

(61)1.

emergency stop switch released.

d. Disassembly. Disassemble by following the sequence

(2) Connect voltmeter positive lead to terminal B+

of figure 3-19.

and the negative lead to terminal 35 of the protective circuit.

e. Inspection of parts.

(1) Visually inspect all parts for evidence of damage,

voltage.

including terminals and wire leads. Pay particular attention to

(3) Turn the key switch on. The voltmeter

the mating surfaces of the diode support (52, fig. 3-19) and

diodes. Clean off the old silicone grease on these surfaces.

3-31

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |