|

|||

|

|

|||

|

Page Title:

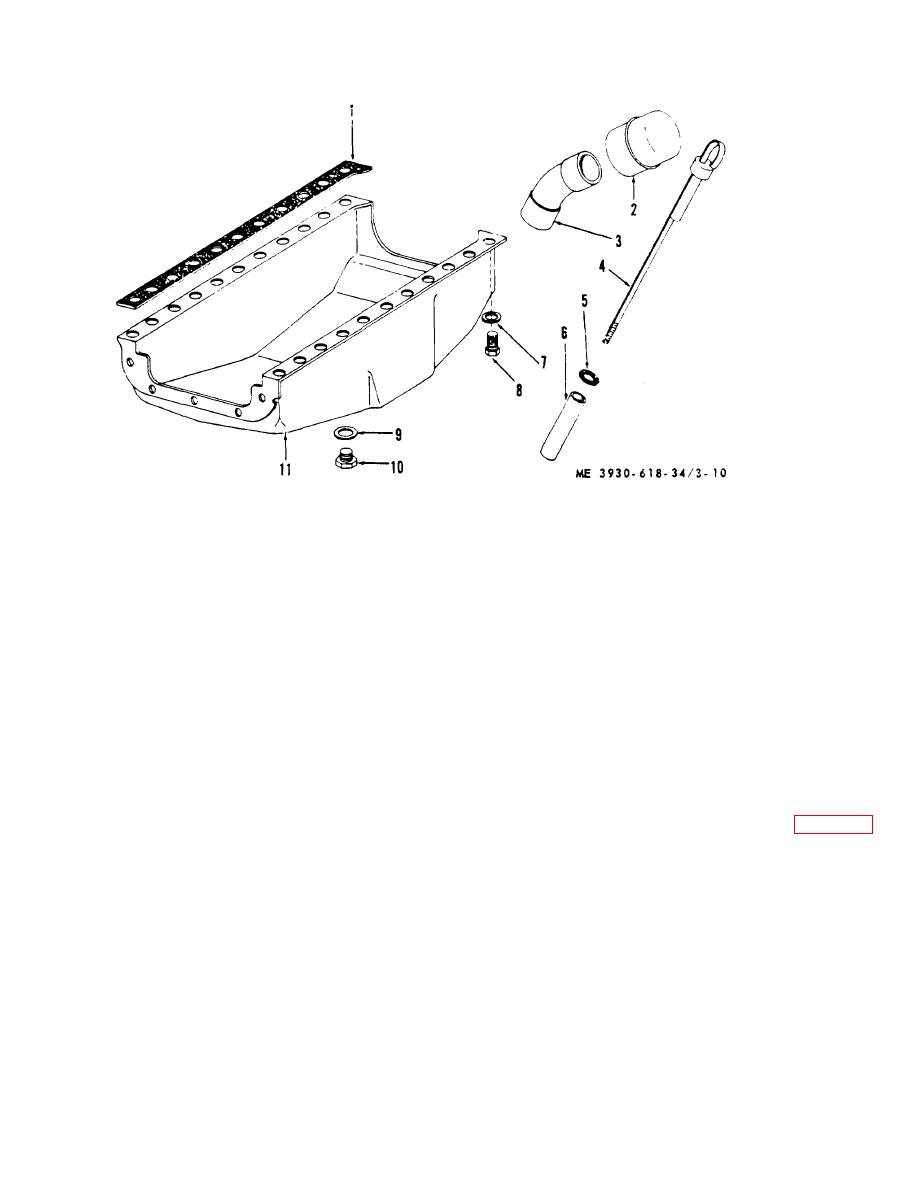

Figure 3-10. Oil pan removal and installation. |

|

||

| ||||||||||

|

|

1 Gasket

7 Lockwasher

2 Breather cap

8 Capscrew

3 Filler tube

9 Gasket

4 Oil level gauge

10 Drain plug

5 Oil seal

11 Oil pan

6 Adapter

Figure 3-10. Oil pan removal and installation.

occurs when starting a cold engine. Surrounding lower

3-13. Oil Pump

part of oil pump is a fine mesh screen to keep any large

a. Description. Lubricating oil pump is the positive

foreign object from entering oil inlet opening and

drive gear type consisting of a single cast pump housing

damaging pump.

and mounting extension with a precision cavity to receive

b. Removal. Oil pump can be removed from

engine without removing engine from truck. Follow

flange by two capscrews. Oil pump drive gear meshes

procedure outlined below. If engine has already been

with and is driven by an integral helical gear on engine

removed, disregard (1) and (2).

camshaft. Oil pump driving gear is pinned to the upper

(1) Distributor is driven by means of an offset

end of pump driving shaft and pump drive gear is

slot at upper end of oil pump driven gear (1, fig. 3-11).

pressed onto lower end of driving shaft. Pump idler gear

Because of offset, distributor can be mounted in only one

is pressed onto idler gear shaft which rotates in pump

position. Therefore, it is recommended that distributor

body. Idler gear is retained in pump body by bottom

rotor be positioned to fire on No. 1 cylinder before

cover in which is located entrance for oil from oil pan. Oil

removing oil pump from cylinder block. This can be

is picked up by the pump gears and is forced into a tube

accomplished by positioning No.

1 piston on

assembly which conducts it to a passage in the filter

compression stroke with timing mark "IGN" in center of

base. Connected to the oil discharge passage of the oil

timing hole in flywheel housing. In this position, piston is

pump body, is a sleevetype relief valve which will bypass

before top dead center. Mark side of distributor housing

oil back to oil pan when discharge pressure exceeds 70-

to indicate position of rotor.

90 psi, thus eliminating undue wear on pump gears

caused by excessively high discharge pressure which

3-16

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |