|

|||

|

|

|||

|

Page Title:

Section XVI. MAINTENANCE OF THE BODY AND OVERHEAD GUARD |

|

||

| ||||||||||

|

|

Section XVI. MAINTENANCE OF THE BODY AND OVERHEAD GUARD

2-62. Seat and Backrest

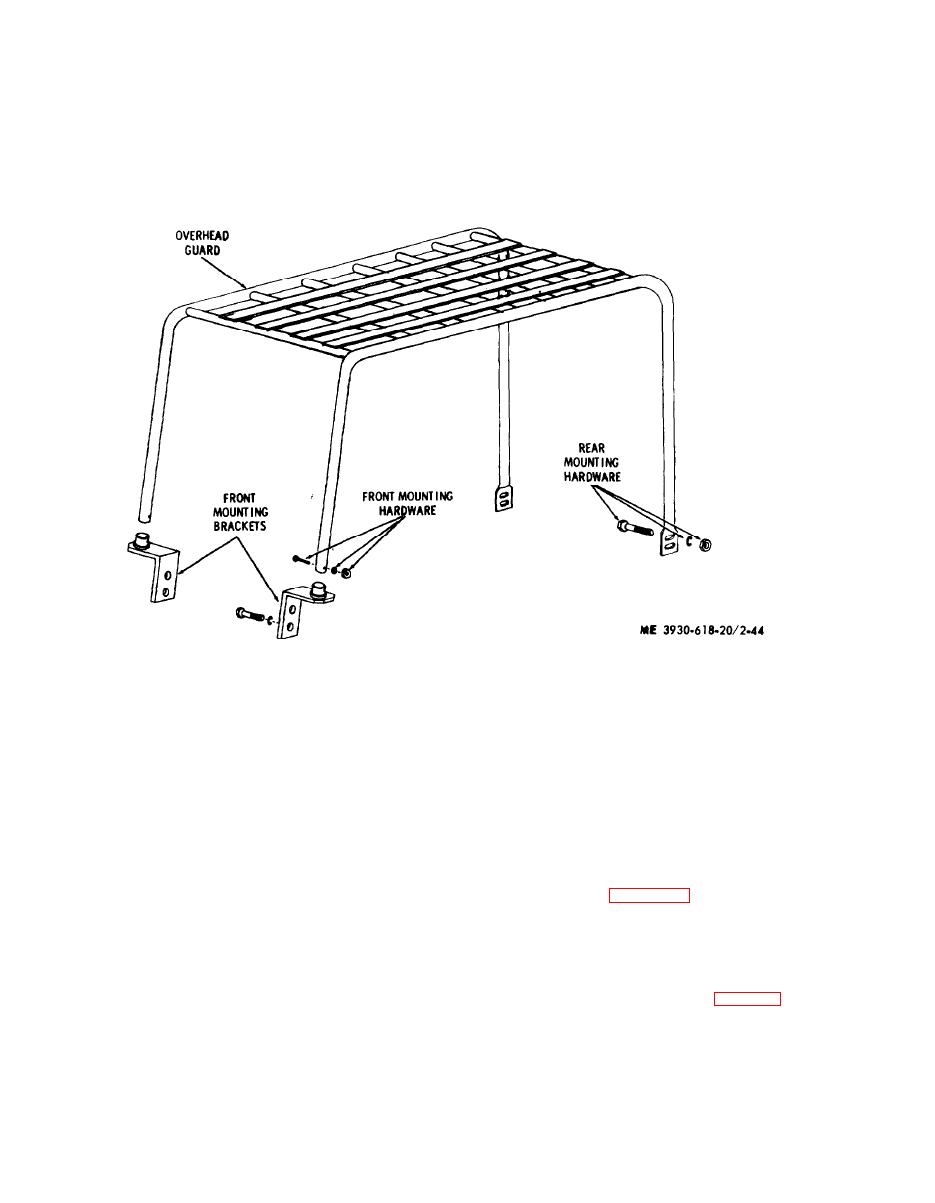

2-63. Overhead Guard

a. Removal.

a. Removal. The overhead guard is removed by

(1) To remove the seat cushion, lift it from the

removing the screws, nuts, and lockwashers that

frame.

secure it to the body.

(2) To remove the backrest cushion, remove the

b. Installation. Reverse procedure in a above.

screws and lockwashers securing it to the frame.

b. Installation. Reverse procedures in a above.

Figure 2-44. Overhead guard. exploded view.

Section XVII. MAINTENANCE OF THE HYDRAULIC LIFT COMPONENTS

2-64. General

2-66. Tilt Cylinder Adjustment

All lifting, steering powering of attachments is

The correct degree of tilt is 3 forward and 10 back-

done by hydraulic pressure. The hydraulic system is

ward. Use a protractor to measure the degree of tilt.

comprised of an oil reservoir, a hydraulic pump coupled

Proceed as follows :

NOTE

to the engine at the rear of the truck, dual control

Make sure the truck is standing level when checking tilt.

valve, lift and tilt cylinders, and the necessary hy-

draulic lines and hoses. An oil filter is installed in the

a. Tilt the mast to the limit of its backward stroke.

pump suction line for the purpose of removing con-

b. Set the protractor for 3 and place it on the back

taminants which may have entered the reservoir. The

of the mast as shown in figure 2-45. The bubble in the

lift cylinder is centrally mounted in the mast assembly.

level of the protractor will center if tilt is correct.

The tilt cylinders are attached to the truck frame and

NOTE

the outer mast channels.

Check both right and left side of the mast and also make sure

both cylinders have come to the end of their stroke

2-65. Hydraulic Pump

c. If adjustment is necessary, tilt the mast to the

Inspect hydraulic pump for leaks or for any other

forward position and loosen the screw (fig. 2-46) on

damage. Report a damaged condition to direct support

the tilt cylinder yoke. Using a wrench, turn the piston

maintenance.

rod by adjusting hex in or out of the cylinder yoke to

obtain the correct tilt angle.

2-50

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |