|

|||

|

|

|||

|

Page Title:

Table 2-2. Troubleshooting - continued |

|

||

| ||||||||||

|

|

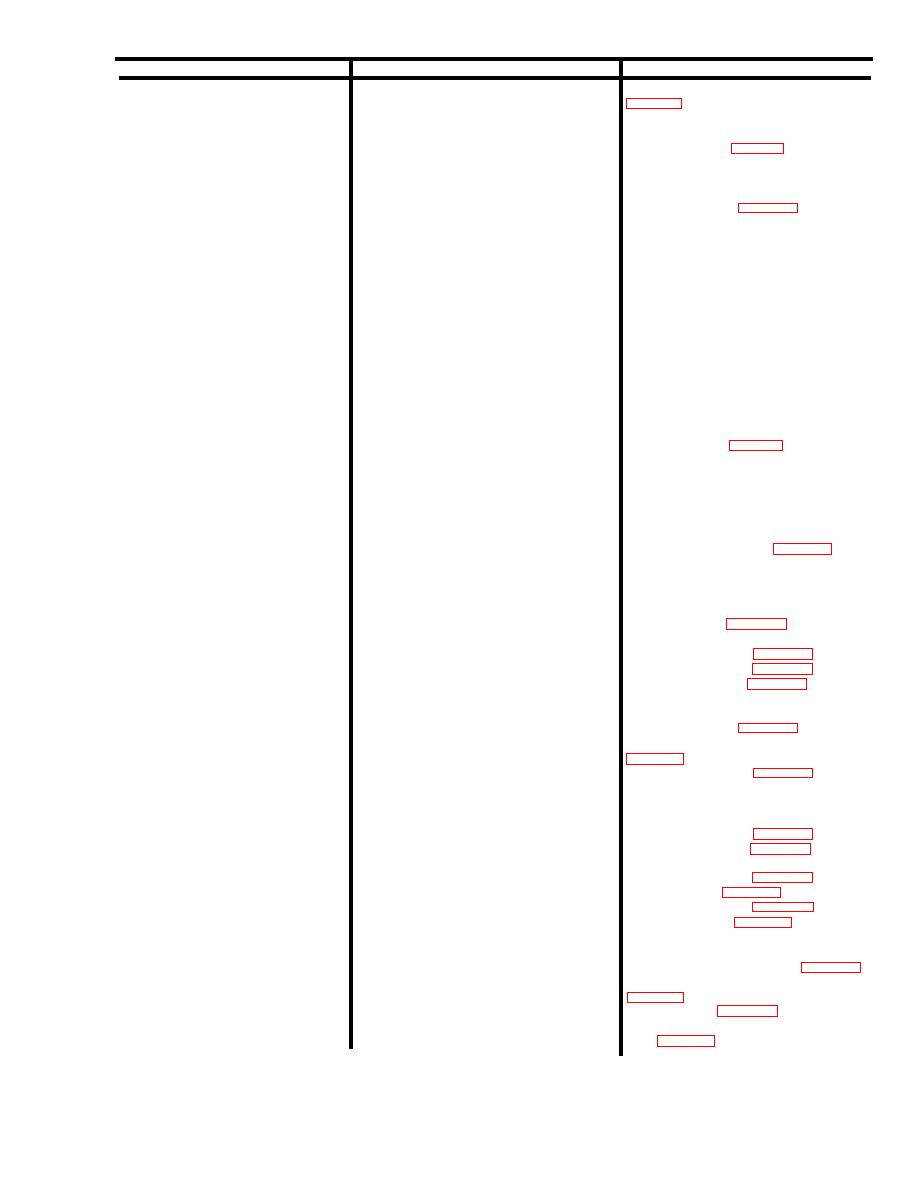

Table 2-2. Troubleshooting (Cont'd)

Probable cause

Corrective action

Malfunction

i. Remove obstructions or replace parts

j. Report to direct support maintenance.

j. Low compression, broken valve springs,

sticking valves

k. Adjust tappets (para 2-8).

k. Improper tappet adjustment.

l. Clean filter. inspect fuel pump, inspect

l. Lack of fuel.

carburetor for water or dirt, and replace if

necessary.

a. Adjust governor (para 2-19).

a. High engine speeds.

13. High oil consumption.

b. Report to direct support maintenance.

b. Oil leak.

c. Use new oil of proper grade.

c. Improper grade of oil or diluted oil.

d. overheating of engine causing thinning of oil.

d. See "engine overheats," item 24 below.

e. Report to direct support maintenance.

e. Defective piston or rings; excessive side

clearance of intake valves in guides; cylinder bores

worn (scored, out-of-round, tapered); worn or

damaged seals.

a. Fill crankcase to prescribed level.

a. Insufficient oil supply.

14. Low engine oil pressure.

b. Change oil, inspect crankcase ventilation,

b. Improper grade of oil or diluted

and inspect for water in oil.

c. Change to proper grade of oil Refer to

c. Oil too heavy.

Lubrication Chart.

d. Report to direct support maintenance.

d. Oil leaks.

e. Report to direct support maintenance.

e. Oil pump faulty; pressure regulator valve

stuck or improperly adjusted, or broken spring.

a. Adjust tappets (para 2-8).

a. Incorrect tappet adjustment.

15. Poor engine compression.

b. Report to direct support maintenance.

b. Leaking, sticking or burned valves; sticking

tappets; valve spring weak or broken; valve stems

and guides worn; piston ring grooves worn or rings

worn, broken or stuck cylinder bores scored or

worn.

a. Fill fuel tank.

a. No fuel in fuel tank.

16. Fuel does not reach carburetor.

b. Replace filter cartridge (para 2-18).

b. Fuel filter clogged.

c. Repair or replace line.

c. Fuel line air leak between tank and fuel

pump.

d. Disconnect and blow out lines.

d. Fuel line clogged.

e. Clean vent.

e. Fuel tank cap vent clogged.

f. Replace pump (para 2-18).

f. Fuel pump defective.

a. Adjust choke control.

a. Choke not closing.

17. Fuel reaches carburetor, but does not

b. Replace carburetor (pars 2-17).

b. Fuel passage in carburetor clogged.

reach cylinders.

c. Replace carburetor (para 2-17).

c. Carburetor float valve stuck closed.

a. Adjust carburetor (para 2-17).

a. Incorrect adjustment of carburetor.

18. High fuel consumption.

b. Reduce -loads to specified minimum

b. Vehicle overloaded.

capacity.

c. Adjust governor (para 2-19).

c. High engine speeds.

d. Clean air cleaner and change oil in cup

d. Air cleaner clogged.

e. Replace carburetor (para 2-17).

e. Carburetor float level too high; acceleration

pump not properly adjusted.

f.

Correct leaks, replace lines.

f. Fuel line leak.

g.

See "Engine Overheats," item 24 below.

g. Overheating engine.

h.

Replace carburetor (para 2-17).

h. Carburetor parts worn or broken.

i.

Replace fuel pump (para 2-18)

i. Fuel pump pressure too high or diaphragm

leaking.

j. Inspect thermostat (para 2-28).

j. Engine runs cold.

k. Reset timing (para 2-14).

k. Ignition incorrectly timed.

l. Replace distributor (para 2-34).

l. Spark advance stuck.

m. Replace gasket (para 2-18).

m. Leaking fuel filter bowl gasket.

n. Report to direct support maintenance

n. Low engine compression.

o. Adjust choke control.

o. Choke partially closed.

p. Adjust carburetor idle speed (para 2-17).

p. Engine idling too fast.

q. Clean and gap or replace spark plugs

q. Spark plug dirty.

r. Replace coil (para 2-36).

r. Weak coil.

s. Remove obstruction or replace, defective

parts (pars 2-23)

2-5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |