|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

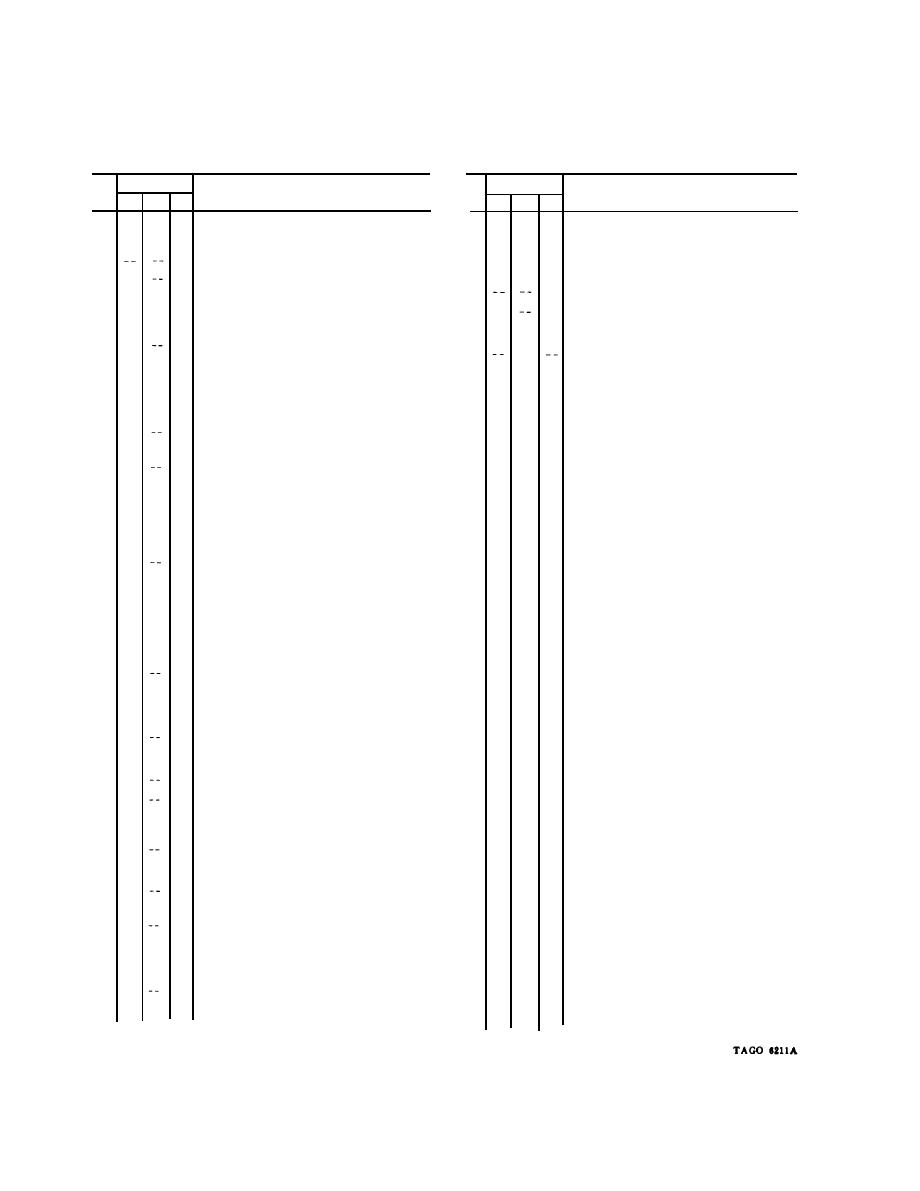

Operator's Checklist

Key :

B-Before-operation service

D-During-operation service

A-After-operation service

Interval

Interval

Item

Paragraph

Paragraph

Item

No. B

Procedure

DA

Procedure

reference

reference

No.

B D

A

tinguisher and the over-

DAILY SERVICES

head guard, is mounted

1

--

FUEL and COOLANT.

properly on the truck.

a. Check the level of fuel

X

x

5

- - LIGHTS.

in the fuel tank. The tank

should be filled to the pre-

X

Check all lights for

X

scribed level.

proper operation.

b. Check the coolant level

X

x

6

--

CONTROLS and INSTRU-

in the radiator. If coolant

MENTS.

level is more than one inch

a. Start the engine and

12b

--

--

X

below neck, have coolant

check the oil pressure gage.

added to the radiator.

The gage should register 10

--

__ B O D Y a n d E N G I N E

pounds of pressure within

COMPARTMENT.

30 seconds. At normal op-

a. Inspect the body of

erating speed, the gage

X

X

should register 20 to 50

the truck and the truck

pounds of pressure at 2000

components for fuel, oil, or

rpm.

water leaks. Be certain to

1 2a

check under the vehicle and

X

--

X

in the engine compartment.

should indicate a h i g h

b. Check the truck for

charge both when the en-

x

X

gine is started and for a

broken or missing compon-

short period thereafter. At

ents and other visible dam-

normal operating speeds,

ages of any nature. Report

the ammeter should indi-

any of these conditions to

cate

a

slight

positive

the proper authority before

charge.

moving the truck.

c. Be certain the hour

12c

c. Be certain that the

X

X

--

X

X

meter begins to operate as

daily lubrication services

soon as t h e e n g i n e i s

on the lubrication order

started.

have been performed.

d. Clean the truck as

d . Allow the engine to

X

X

12f

--

X

X

necessary.

idle for at least 2 minutes,

and check the water temp-

--

--

TIRES.

3

erature gage. During the

a. Inspect the tires for

X

X

warmup period, the temp-

erature reading should

unusual wear, cuts, and the

gradually rise to the

presence of foreign objects.

normal operating range of

b. Check the tires for

X

X

160 to 180F.

proper inflation of 100 psi.

e. Check the fuel gage

12d

4

--

--

FORMS and SAFETY

to be sure it indicates a full

EQUIPMENT.

tank of fuel.

a. Be certain the neces-

X

X

f. Check converter o i I

12e

X

--

sary forms prescribed in

temperature warning light.

TM 38-750 are on the

If light glows any time

truck.

during operation, stop the

b. Check the truck to be

X

X

engine a n d r e p o r t t h e

certain all safety equip-

trouble to the proper au-

ment, such as the fire ex-

thority.

14

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |