|

|||

|

|

|||

|

|

|||

| ||||||||||

|

|

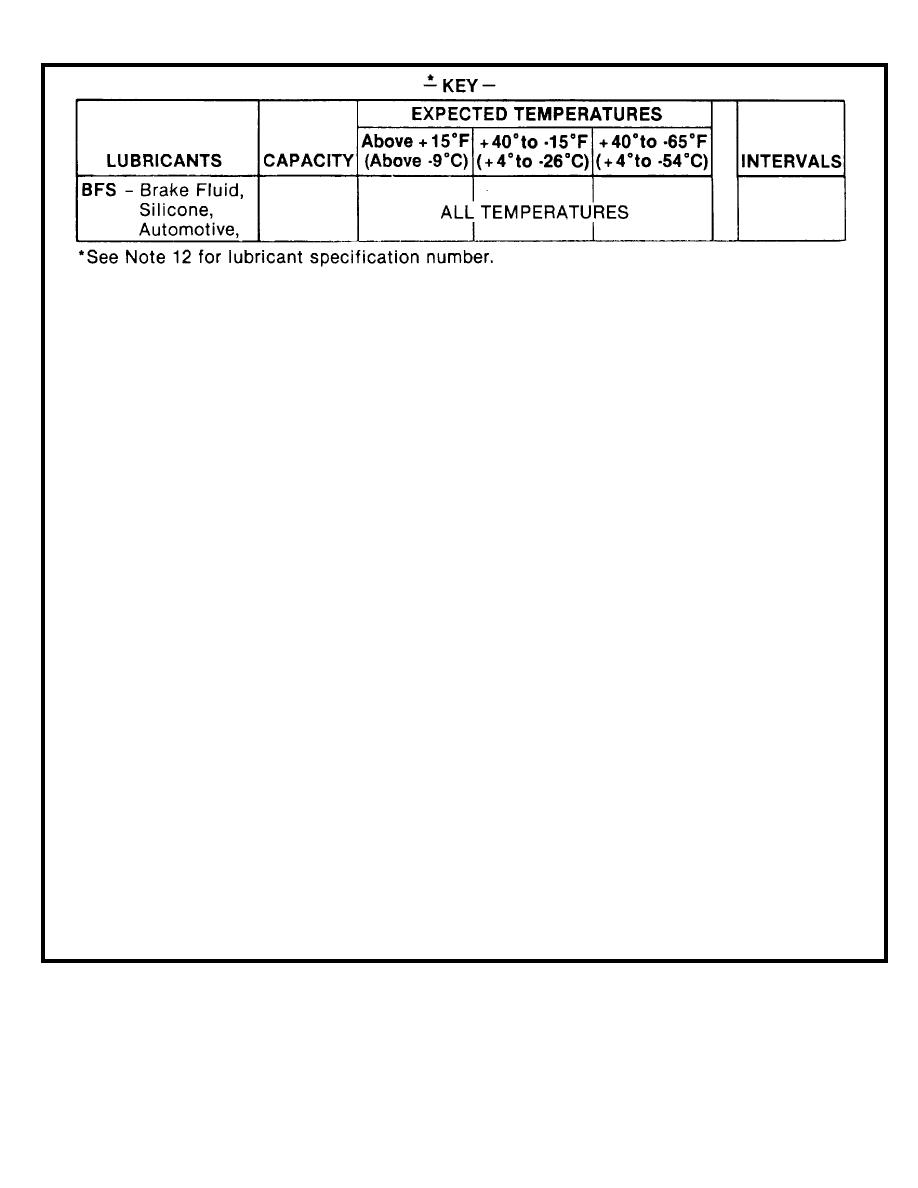

1. FOR

OPERATION

OF

EQUIPMENT

IN

7. TRANSMISSION OIL FILTER. Filter element is to

PROTRACTED COLD TEMPERATURES BELOW -

be replaced every 1000 hours. Remove filter element,

150F (-260C). Remove lubricants prescribed in Key for

clean housing, install new filter element.

After

temperatures above -15F (-260C). Relubricate with

replacement, with engine running at idle speed, oil at

lubricants specified in Key for temperatures below -150F

operating temperature and transmission in neutral, check

(-260C). If OEA lubricant is required to meet the

housing for leaks, check transmission oil level and bring

temperature ranges prescribed in the Key, OEA lubricant

to "FULL" mark.

is to be used in place of OE/HDO-10 lubricant for all

temperature ranges where OE/HDO-10 is specified in

8. TRANSMISSION AND TORQUE CONVERTER.

the Key.

Check oil level each 90 hours with engine running at idle

speed, oil at operating temperature and transmission in

2. OIL CAN POINTS. Each 250 hours lubricate throttle

neutral. Maintain oil level to "FULL" mark. Operate for 5

minutes, check for leaks and bring transmission oil level

handle, hood latches and seat adjuster with OE/HDO.

to "FULL" mark.

3. MAST, CARRIAGE, AND CHAIN ROLLERS. Inject

9. HYDRAULIC SYSTEM OIL FILTER.

lubricant through rubber seal with hypodermic syringe

Filter element is to be replaced every 1000 hours. Drain

and needle.

hydraulic reservoir, disconnect hydraulic hose, remove

filter, flush reservoir, replace filter element, install filter,

4. HAND BRAKE LEVER SHAFT. Remove floor plate,

connect hose, fill reservoir. Operate hydraulic system for

lubricate using gun with flexible connection, install floor

5 minutes, check for leaks, check oil level and bring to

plate.

"FULL" mark.

5. ENGINE OIL LEVEL HOT OR COLD CHECK. Cold

10. HYDRAULIC RESERVOIR FILL CAP AND

engine, oil level should be at high mark on dipstick. Hot

BREATHER. Each 10 hours, clean breather by tapping

engine, oil level must be between high and low marks on

on a wood block or bench. Replace if excessively dirty.

dipstick (allow to set 5 minutes before checking).

11. STEERING GEAR. Check level each 250 hours.

6. ENGINE OIL FILTER. Filter element is to be

Change gear lubricant only when required by

replaced each 250 hours. Remove filter element, clean

maintenance repair action, contamination by water, or

housing, install new filter element. After replacement, fill

other foreign material. After refill operate for 5 minutes,

crankcase, operate engine 5 minutes, check housing for

check for leaks and bring oil to level of level plug

leaks, check crankcase oil level and bring to "FULL"

opening.

mark.

TA220149

LO 10-3930-237-12

CARD 4 OF 5

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |