|

|||

|

|

|||

|

Page Title:

ALTERNATOR REPAIR/TEST - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

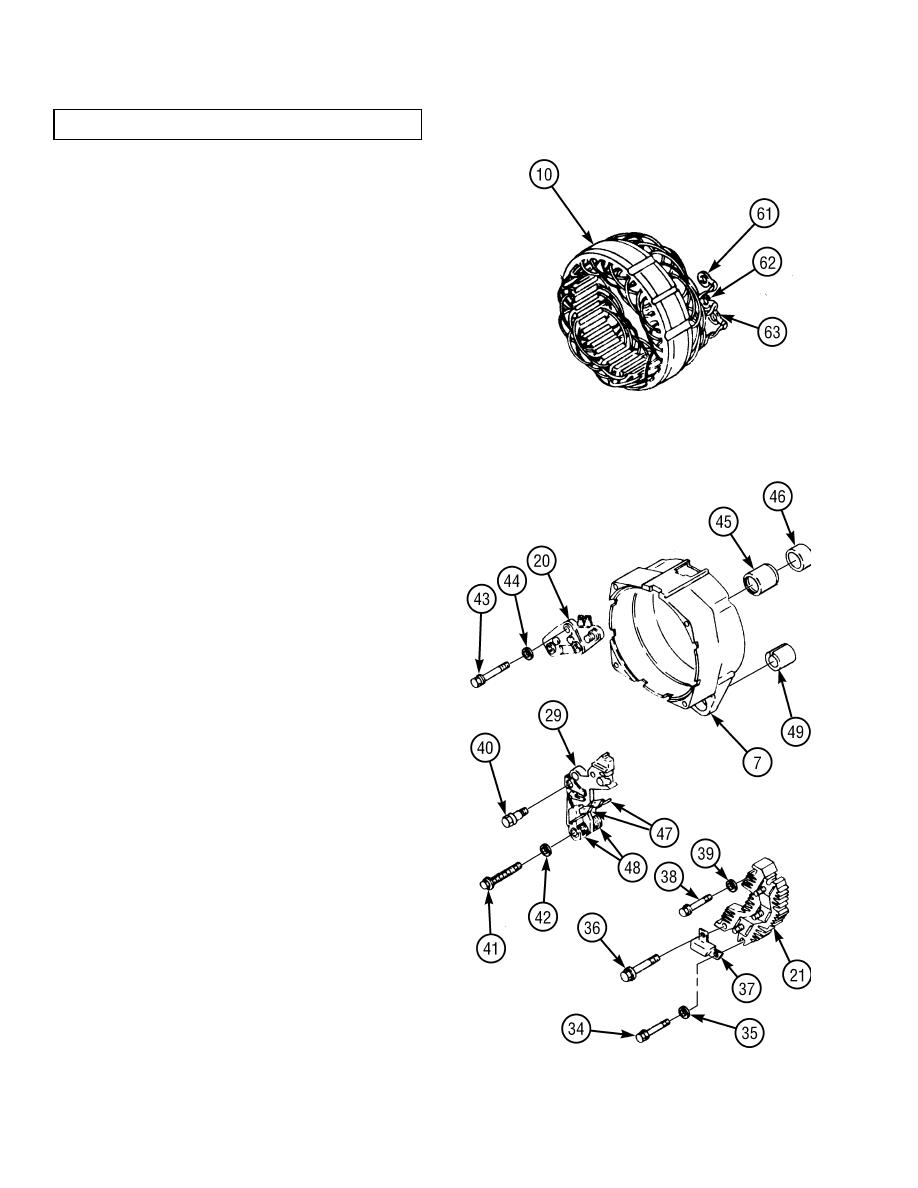

6-3. ALTERNATOR REPAIR/TEST (CONT)

(4)

Test stator assembly (10) for open or

grounded windings.

(a)

Using a multimeter set to ohms, low

scale, measure resistance through stator

windings. Connect multimeter to terminal

clips (61 through 63), from each outside

clip to center clip and then between two

outside clips.

(b)

Measure resistance from each terminal

clip (61 through 63) to stator frame to

check for grounded windings. A low

resistance reading between any terminal

TR01433

clip and stator frame indicates a grounded

winding, and stator (10) must be replaced

as a unit.

e. Assembly.

(1)

Using suitable press, install bushing (49) on

rear frame (7).

(2)

Position two springs (48) and brushes (47) on

brush holder assembly (29).

(3)

Install roller bearing (45) in rear frame (7).

(a)

Pack roller bearing (45) with lubricant.

(b)

Using a suitable press, install bearing (45)

into rear frame (7). Bearing side should

be flush with inside base of frame (7).

(c)

Install cap (46) in rear frame (7).

(4)

Install regulator (20) on rear frame (7) with

washer (44) and screw (43).

(5)

Install brush holder assembly (29) on rear

frame (7) and regulator (20) with washer (42)

and screw (41) and insulated screw (40).

(6)

Install rectifier bridge assembly (21) on rear

frame (7) with washer (39) and screw (38).

(7)

Install capacitor (37) on bridge rectifier

assembly (21) with washer (35), screw (34),

and insulated screw (36).

6-8

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |