|

|||

|

|

|||

|

Page Title:

TURBOCHARGER ASSEMBLY REPAIR - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

TR01403

(6)

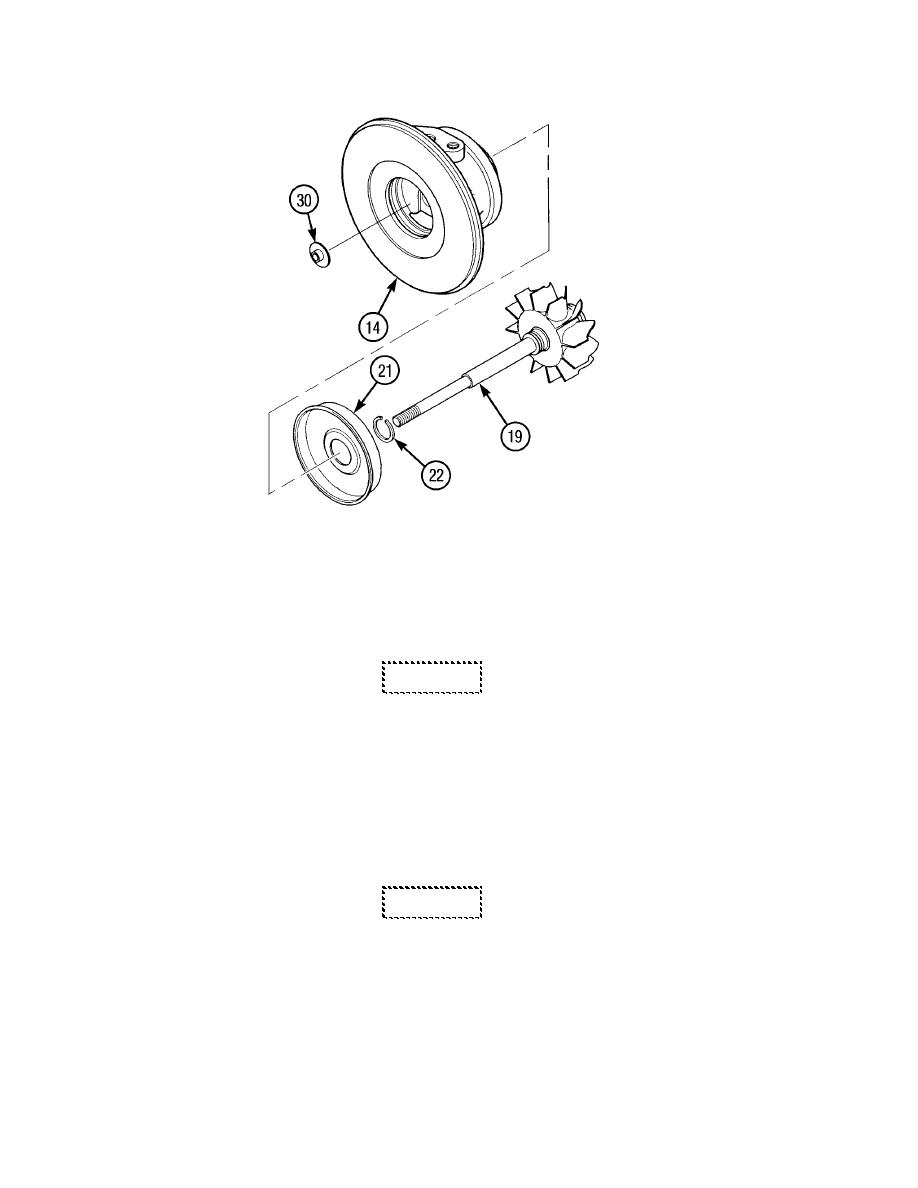

Position heat shield (21) on bearing housing (14).

(7)

Install seal ring (22) on shaft and wheel (19).

CAUTION

Ensure that seal ring gap is positioned 180 from bearing housing drain hole to prevent

damage to turbocharger assembly.

(8)

Install shaft and wheel (19) and seal ring (22) as an assembly in bearing housing (14).

(9)

Apply engine oil on shaft and wheel (19) shaft.

(10)

Support shaft and wheel (19) and bearing housing (14) in a suitable fixture.

CAUTION

When installing thrust collar ensure balance mark on collar is aligned with shaft and

wheel shaft balance mark. Mark top surface of thrust collar so alignment can be verified

after installing thrust bearing . Failure to align balance marks could cause premature

component failure.

(11)

Install thrust collar (30) on shaft and wheel (19).

4-27

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |