|

|||

|

|

|||

|

Page Title:

ENGINE OIL PUMP REPLACEMENT - continued |

|

||

| ||||||||||

|

|

TM 10-3930-673-34

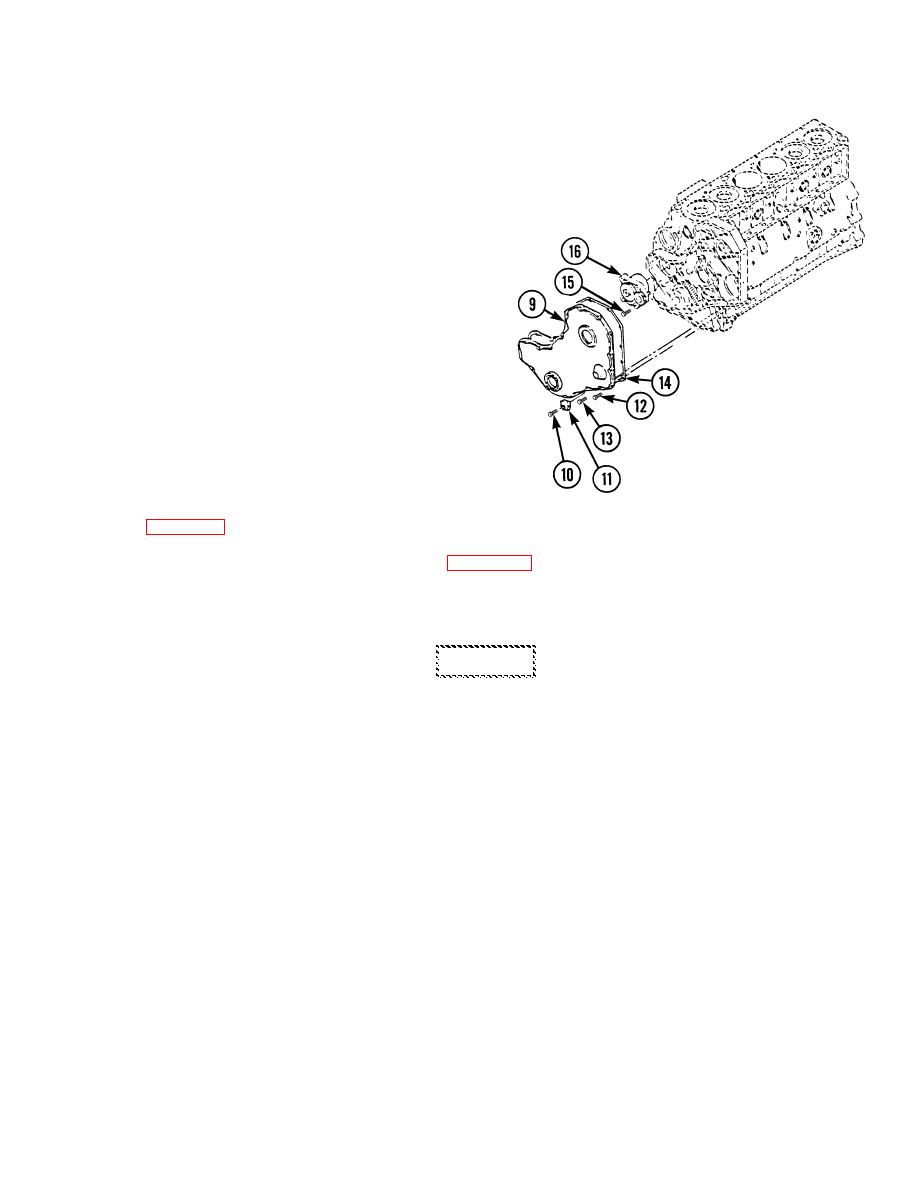

NOTE

Screws which retain timing gear

cover are of three sizes. Note size

and location of screws before

removal to allow correct location at

assembly.

(6)

Remove gear cover (9).

(a)

Remove screw (10) and belt

guide (11).

(b)

Remove 11 screws (12) and eight

screws (13) from gear cover (9).

(c)

Remove gear cover (9) and

gasket (14). Discard gasket.

(7)

Remove four screws (15) and oil

pump (16).

TR00987

b. Cleaning. See Cleaning Instructions

d. Installation.

CAUTION

When installing oil pump, be sure idler gear pin is installed in the locating bore in the

cylinder block. Failure to properly locate oil pump can result in damage to oil pump and

to cylinder block bore.

(1)

Using engine lubricating oil lubricate oil pump (16).

NOTE

Filling oil pump with oil prior to installation will help to prime oil pump at engine

start-up.

Back plate on oil pump seats against bottom of cylinder block bore. When oil pump is

correctly installed, flange on pump will not touch cylinder block.

(2)

Install oil pump (16) and four screws (15). Tighten screws in opposite pairs to 216 lb-in

(24.40 Nm).

3-145

|

|

Privacy Statement - Press Release - Copyright Information. - Contact Us |