| |

TM 10-3930-671-24

5.

Do not repair chains by cutting out the worn sec tion

and joining in a new piece.

6.

If part of a chain is worn, replace all the chains or the

truck.

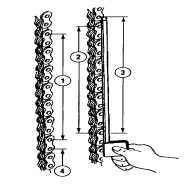

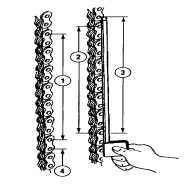

Lift Chain Inspection and Wear Criteria

NOTE

Take measurement while chain is under

tension when lifting a small load.

1.

New Chain Length - The distance from the firs pin

counted to the last pin counted in a span while the

chains are lifting a small load.

2.

Worn Chain Length - See (1) above.

3.

Span - The number of pins in the length (segment,

of chain to be measured, including the first one.

4.

Pitch - The distance from the center of one pin to

the center of the next pin.

Figure 4. Measuring chain for wear, using tape measure.

Table of Chain Dimensions

Leaf Chain

Chain No.

Pitch

Span

Worn Chain Length

BL800

1.00 in. (25.4 mm)

13

12.375 in. (314.3 mm)

Lift Chain Replacement

1.

All chains must be replaced if any strand has

wear of 3% or more, or if any of the chain-

damage conditions noted previously are found

during inspection.

2.

Replace all chains as a set (in pairs). It is

impossible to keep a balanced loading and wear

life between chains if a new chain is put into

service opposite an old chain. Inequities

between the new and the older, worn chain will

cause problems in keeping chain tension equal,

accelerated wear, and probable early failure.

3.

Order replacement chains as required.

4.

Do not remove the factory lubrication from new

chains. It helps prevent wear and corrosion. If

the original lubricant has dried or been removed,

apply lubricant as specified in Lubrication Order

(Appendix B).

5.

Do

not

paint

new

chain

before

or

after

installation. Paint may help prevent corrosion,

but will also prevent lubricant from reaching the

pins for good joint lubrication.

6.

Carefully

inspect

the

chain

anchors

and

sheaves. Broken, cracked, or worn anchors

must be replaced. Replace worn sheaves, and

check the sheave bearings for wear.

7.

Use new anchor pins when installing new chains.

8.

Adjust the tension on new chains.

9.

Lubricate chains when they are installed on the

upright.

Fork Removal

1.

Release the fork latches and move each fork to

the notch on bottom of carriage.

F-500

|