| |

TM 10-3930-671-24

5.

Check hydraulic system relief pressure setting at

full throttle. Accelerate the engine to no-load

governed speed (full throttle), and hold at this

speed while obtaining the pressure readings.

6.

Move the tilt control lever to full back (or forward)

tilt relief position. Hold tilt control in relief

position until pressure reading is obtained, and

then release.

NOTE

Do not operate system over relief any

longer than required to read the

pressure gauge.

Hydraulic System Relief Pressure

Specifications

GPX 25E

2600-2700 psi

Reference Section 2. 1, Service Specifications.

Relief Pressure Adjustment

NOTE

If adjustment is necessary, do not

exceed the relief pressure setting

specified for the truck model capacity

rating. Changing the pressure will

not increase lifting capacity or lifting

speed.

1.

Remove the valve cover from the seat support

plate for access to the relief valve adjustment

screws on the main valve.

2.

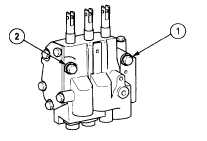

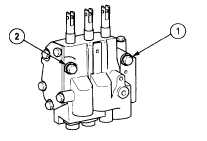

The main hydraulic system relief (1) and aux

relief (2) valve adjustment screws are located on

the upper front side of the main valve.

To adjust, loosen the lock nut, reset and tighten lock

nut. Turn adjustment screw clockwise (CW) to increase

pressure. Turn counterclockwise (CCW) to decrease

pressure.

3.

If pressure relief valve needs to be adjusted,

loosen the lock nut, hold the control lever in relief

position, and turn the relief pressure adjustment

screw until pressure gauge reads the correct

relief pressure setting. Tighten the lock nut.

4.

IMPORTANT - Recheck the relief pressure

setting. With engine running at full throttle, move

the control lever to relief position and read the

pressure gauge. This is to verify that relief

pressure setting has not been changed during

the tightening of the locknut.

5.

If pressure setting is not correct, repeat the

adjustment procedure.

6.

When

relief

pressure

setting

is

correct,

disconnect the pressure gauge. Put the cap on

the quick disconnect fitting. Install the cover

enclosing main valve.

7.

Close

the

engine

compartment,

remove

blocking, and lower drive wheels to the floor.

This completes the procedure for checking and adjusting

main hydraulic relief pressure.

F-456

|