| |

TM 10-3930-671-24

3.

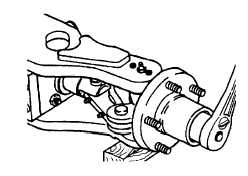

Loosen spindle (bearing adjusting) nut. (If nut

completely removed, see below).

4.

After spindle nut is loosened, hit the top of wheel

(tire) to loosen (unseat) the bearings. This

moves the bearings free of their seated, running

position.

5.

Tighten spindle (bearing adjusting) nut until there

is a slight binding or drag in the bearings as

wheel is rotated by hand in both directions.

Then, back nut off to nearest slot in nut and lock

with cotter pin. Bend tabs on cotter pin.

6.

Check again for correct bearing adjustment by

rotating the wheel by hand. Wheel should rotate

freely or with only slight "drag." Readjust

bearings by adjusting spindle nut, as necessary,

to avoid binding in bearings.

7.

Pack the area around spindle nut with grease.

8.

Install hubcap by tapping into place with a rubber

or plastic-faced hammer.

Steer Wheel Bearing Lubrication

(Clean, Repack & Adjust Bearings)

Refer also to wheel bearing adjustment procedures

noted previously.

WARNING

Be sure truck is parked and blocked

up correctly and safely to prevent

injury to personnel or damage to

equipment.

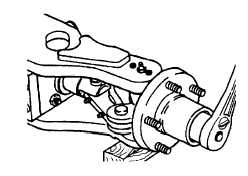

1.

Raise steer wheels off the floor.

Refer to Section 3.3, Machine Jacking & Blocking.

NOTE

Because of the heavy weight of the

wheel and tire, it is suggested to first

remove the wheel and tire assembly

from

hub

when

servicing

the

bearings to avoid damage to the

grease seal when the wheel hub is

moved off or on the spindle. It also

makes the work simpler and easier.

2.

Loosen wheel bolts or lug nuts before completely

raising rear wheels off the floor.

3.

Lower truck onto blocking. Remove wheel bolts

or lug nuts, and then wheel assembly from the

hub.

4.

Loosen and remove the hubcap from wheel hub.

You may have to lightly tap hub cap with a

hammer and chisel and use a pry bar to loosen.

Be careful not to damage mounting surfaces.

5.

Clean the excess grease from around the

spindle nut.

6.

Remove cotter pin, loosen and remove spindle

nut and bearing washer.

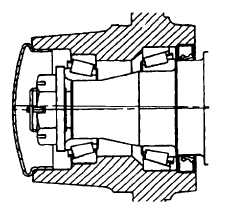

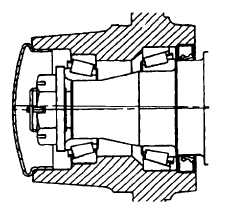

7.

Pull out on the wheel hub slightly to loosen

bearings, then remove outer bearing.

8.

Pull the wheel hub off the spindle. Support the

wheel hub to avoid dragging the grease seal at

the back side across the thread on spindle end.

9.

Clean the old grease out of center of wheel hub.

F-422

|