| |

TM 10-3930-671-24

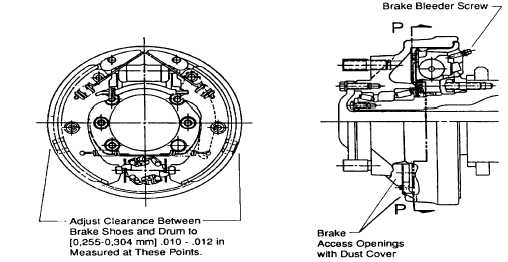

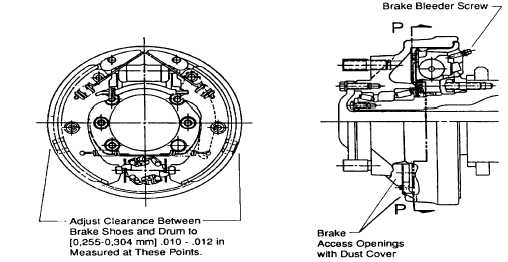

Service Brake Adjustment

Figure 4. Service Brake Installation

NOTE

•

Engine should not be running.

•

Remove key for safety.

•

Be

sure

transmission

directional

control is in NEUTRAL and truck

prevented from moving when parking

brake is released.

1.

The service brakes on the TA18 transaxle may

be adjusted from the inner side through the

backing plate (all models), or from the outer side

through access openings in the wheel hub/brake

drum (later models).

2.

Brake clearance is measured between brake

shoe and drum, with brakes fully released. Brake

Clearance: .010-.012 in. (0.255-0.304 mm)

3.

Release parking brake.

IMPORTANT - Do not overtighten brakes. It is very

difficult to release the ratchet wheel pawl and back

off adjustment of the brake.

1.

Adjustment thru Backing Plate

1.

Remove the 4 dust plugs in brake backing plate.

2.

Use a feeler (thickness) gauge to check the

clearance between each shoe and drum. Use a

screw driver or equivalent tool to rotate the

adjustor ratchet wheel in the brake.

Some brake linings are still made with asbestos which

when inhaled has been found to be extemely dangerous.

Do not use compressed air to clean the brake shoes or

other parts before or after disassembly. Instead wipe

down the assembly and then the components with damp,

disposable wipers and immediately discard them safely.

Avoid breathing any dust or injury may result.

3.

Use a screwdriver to push on and release the

ratchet pawl when it is necessary to vback off

adjustment (increase clearance) of the brake.

4.

Carefully adjust clearance between brake shoes

and drum to .010-.012 in. (0.255-0.304 mm)

measured at dust plug openings at outer sides of

backing plate.

5.

Replace the dust plugs in brake backing plate

when adjustment is completed

F-377

|