| |

TM 10-3930-671-24

3- Ring and Pinion Gear Replaced

If only the ring and pinion were changed, the following

procedure is used:

SHIM PACK THICKNESS CALCULATIONS Use a

micrometer to measure the original shim pack thickness.

1.

If the new pinion mounting distance (etched on

ring gear) is larger than the pinion mounting

distance (etched on original ring gear), you must

subtract the difference (see following example):

5.904

etched on new ring gear

-5.901

etched on original ring gear

0.003

difference

D.

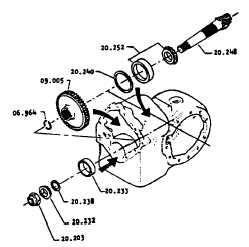

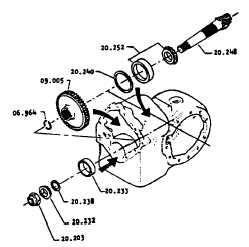

Pinion Gear Installation

1.

Install the pinion inner bearing cup shim pack

and bearing cup in the transmission case.

2.

If outer bearing is removed or replaced, install

outer pinion bearing cup in transmission case.

3.

Assemble the inner pinion bearing on the pinion

shaft.

4.

Position the output gear in the case with the long

hub of the gear outward as shown.

5.

Position the pinion shaft and inner bearing into

the case and through the output gear.

6.

Install the output gear retainer ring on the pinion

shaft. Be sure the retainer ring is fully seated into

the ring groove.

0.031

original shim pack

-0.003

difference

0.028

FINAL SHIM PACK (E)

2.

If the new pinion mounting distance is smaller

than the pinion mounting distance on the original

ring gear, you must add the difference (see

following example).

5.905

etched on new ring gear

-5.901

etched on original ring gear

0.004

difference

0.031

original shim pack

+0.004

difference

0.035

FINAL SHIM PACK (E)

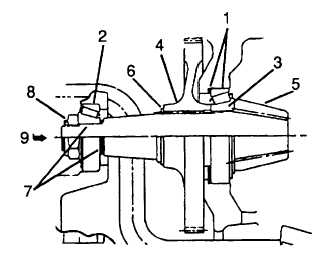

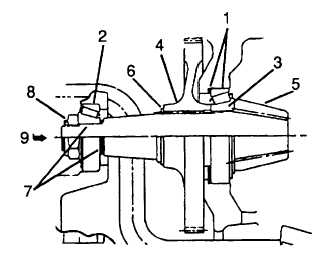

7.

Assemble the outer bearing shims and outer p i

n ion bearing on the pinion shaft. If a new pinion

shaft is used, a nominal shim pack of .062 in.

(1.575 mm) can be used initially.

8.

Install the pinion shaft nut and tighten to torque

spec: 200-250 lb-ft. (271-339 Nom). Hold or

block the pinion shaft with a brass bar or similar

soft material to prevent the shaft from turning.

9.

With pinion shaft free to turn, use a torque

wrench to measure the pinion shaft bearing

rolling-torque preload.

Preload torque spec. 7-15 lb-in. (0.8-1.6 N-m)

NOTE

Remove pin ion shaft nut and bearing and add or

remove shims behind pinion shaft outer bearing

cone to set correct bearing preload torque.

F-369

|