| |

TM 10-3930-671-24

TA18 SERVICE MAINTENANCE

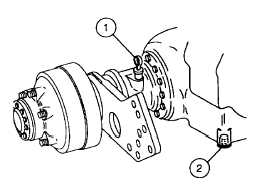

The TA18 transaxle has two service openings:

1.

Dipstick/oil fill tube, in left side axle housing.

2.

Drain plug, in bottom of transmission case.

Fluid Level Check

Check the transaxle fluid level with:

• Truck on a level surface.

• Engine idling with transmission in NEUTRAL.

• Oil at operating temperature (1800 - 2000F)

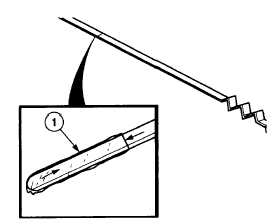

1. Clean area around oil filler before removing

dipstick. Pull dipstick out. Remove all oil from

dipstick with a clean wiper and push it back into

filler tube. Remove dipstick to check oil level.

2. The oil level is correct when oil can be

measured between the marks on dipstick.

3. Add recommended fluid only, as required.

4. After adding oil to transaxle, wait several

minutes

until

oil

has

distributed

evenly

throughout the unit. Check for correct oil level.

Do not overfill.

NOTICE

The follow lubricant is recommended for best

operation of the TA18 transaxle:

AMOCO 1000, or Texaco 1893 TDH

Clark Part No. 2776236

Fluid and Filter Change

It is recommended to:

•

Drain and replace the transaxle fluid every 1000

operating hours.

•

The oil should be drained when warmed to operating

temperature, 180°-200°F (82°-93°C).

•

Replace the transaxle oil filter every 500 operating

hours. See NOTE below.

TA 18 Transaxle dipstick/oil fill tube.

NOTE

When the transaxle is new or rebuilt, it is recommended

to change the oil filter after the first so hours and again

after 100 operating hours.

1. Remove drain plug from bottom of transmission

case. Drain old oil into suitable drain pan.

2. Remove old oil filter. The oil filter is mounted

near the top of converter housing above

transmission.

NOTE

Take special care when removing the filter to avoid oil

remaining in filter from draining onto floor. Loosen the

filter using a filter wrench. Remove filter while holding a

pad of cloth or other absorbent material under the open

end to absorb any excess oil that may drain out of filter.

3. Install a new oil filter. Follow the installation

instructions printed on filter.

Refilling The Transaxle

After drive axle and transmission housing has drained

completely:

1. Install drain plug.

2. Remove dipstick and fill transaxle to FULL mark

on dipstick. Do not overfill.

3. Start the engine and run at idle speed (500-700

rpm) in NEUTRAL for 2-3 minutes to prime the

converter and cooler lines.

4. Recheck oil level with engine running at idle

speed. Add oil to bring oil level to ADD mark on

dipstick. When oil temperature is hot (180 -

200°F), make final oil level check. Oil level

should be at FULL mark.

5. Check for leaks at drain plug and oil filter.

F-348

|