| |

TM 10-3930-671-24

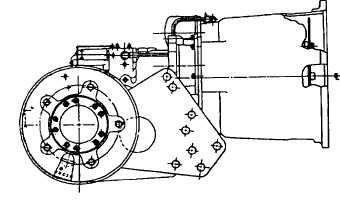

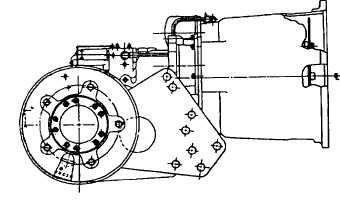

7.6. TA18 Transaxle

Description and Operation........................................................................................ F-345

Specifications ........................................................................................................... F-346

TA 18 Service Maintenance ..................................................................................... F-348

General Arrangement............................................................................................... F-350

Parts Nomenclature.................................................................................................. F-351

Transaxle Overhaul .................................................................................................. F-359

Service Brake Adjustment ........................................................................................ F-377

Description and Operation

Refer to Section 2.1, Service Specifications for TA-18

Clark Model TA18 transaxle assembly includes:

• Torque converter

• Single-speed forward and reverse power shift

transmission with integral differential and drive axle

• Full-floating straight drive axle-drum-and shoe brakes

• Gear-driven pump drive

• Electric shift control, hydraulic inching control

Powerflow is from torque converter turbine to turbine

(clutch) shaft and gears then thru either forward gear or

reverse idler shaft to output gear mounted on final drive

pinion shaft.

Transmission and differential housed in one-piece

transmission case. Torque converter housing joined to

transmission case through an adaptor (or spacer) plate.

Adaptor plate holds converter stator support and reverse

idler outer bearing.

Pump drive driven by converter impeller hub gear

through idler gear to pump gear mounted on charging

pump shaft.

Final drive pinion gear shaft mounted in tapered roller

bearings at both ends in transmission case, and adjusted

for mounting distance and ring and pinion gear contact

by shim pack installed behind inner tapered roller bearing

cup at pinion gear in transmission case. Pinion shaft

bearing preload is adjusted with shims behind outer

bearing cone on pinion shaft.

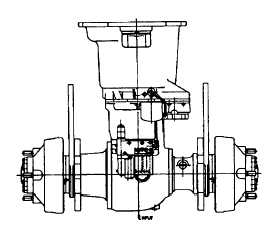

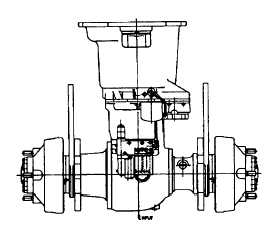

Final drive ring gear bolted to differential carrier.

Differential supported by opposed tapered roller bearings

mounted on inner ends of wheel end housings, which are

bolted to openings in transmission case at the sides of

the differential. Differential bearing preload and ring gear

clearance (backlash) is maintained by shims placed

behind differential bearing cones on wheel end housings.

Adjustment of differential bearing preload or ring gear

backlash requires trial assembly, checking, and

disassembly of wheel end housings until correct

adjustment is obtained.

Drive axle wheel hubs/brake drums supported by double

tapered roller bearings on outer end of wheel end

housings. Drive axle shaft flanges bolted to wheel hubs

and full-floating in differential. Service brake backing

plates bolted to mounting flanges on wheel end

housings. Wheel bearings lubricated from transaxle

sump.

Control valve mounted on pad at top of transmission

case. Oil from charging pump flows thru filter and

pressure regulator to control valve thru external oil

supply

F-345

|