| |

TM 10-3930-671-24

TA18 Service Points

Refer to Section 7.6, TA 18 Transaxle, for additional

information.

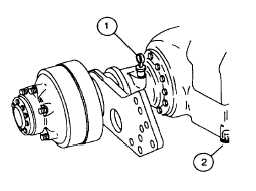

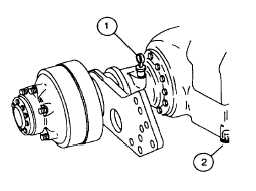

The TA18 transaxle has two service openings:

1

Dipstick/oil fill tube, in left side axle housing

2

Drain plug, in bottom of transmission case

IMPORTANT

Recommended lubricant for TA18 transaxle:

AMOCO 1000, Texaco 1893 TDH, or Gulf

303

Part No. 2776236

Transaxle Fluid Level Check

Check the transaxle fluid level with: ·

•

Truck on a level surface

•

Engine idling w/transmission in NEUTRAL

•

Oil at operating temperature (180-200-F)

Check the PM time interval (operating hours), or the

condition of the oil to determine if the transaxle fluid

needs to be changed.

NOTE

Also refer to Section 2.1, Service

Specifications, for transaxle-model

recommended oil specification.

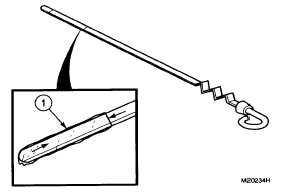

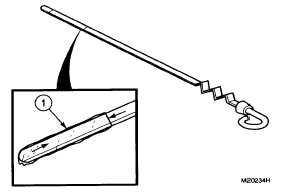

See illustration above.

Clean area around oil fill tube before removing dipstick.

Pull dipstick out. Remove all oil from dipstick with a

clean wiper and push it fully back into oil fill tube.

Remove dipstick to check oil level.

Correct Oil Level

1. The oil level is correct (FULL) when oil can be

measured on the dipstick.

2. Add recommended fluid only, as required.

3. After adding oil to transaxle, wait several

minutes

until

oil

has

distributed

evenly

throughout the sump. Check for correct oil level.

Do not overfill.

Transaxle Fluid and Filter Change:

Drain and Refill

It is recommended to:

•

Drain and replace the transaxle fluid every

1000 operating hours.

•

Remove and clean the transmission sump

oil

strainer

screen

each

time

the

transmission

fluid

is

changed

(on

applicable models).

•

The oil should be drained when it is

warmed to operating temperature, 160-

200°F (82-93°C).

•

Replace the transaxle oil filter every 500

operating hours or every 6 months,

whichever occurs first. See below.

When the transaxle is new or rebuilt,

it is recommended to change the oil

filter after the first 50 hours and again

after 100 operating hours. This is to

ensure that the oil is cleaned of any

harmful

particles

which

may

be

loosened or flushed off new parts as

they wear in. Failure to change the

oil filter may result in damage to

transaxle.

Draining The Transaxle

Minimum Tools Required:

•

22 mm socket wrench

•

1/2" square drive

•

Drain pan

F-320

|