| |

TM 10-3930-671-24

1.

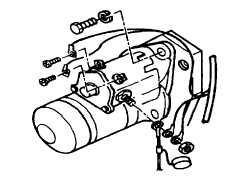

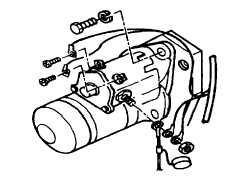

Remove the battery ground () cable.

2.

Disconnect wiring from the starter and solenoid.

3.

Remove the starter mounting bolts (2).

4.

Remove the starter.

Starter Overhaul Disassembly

1.

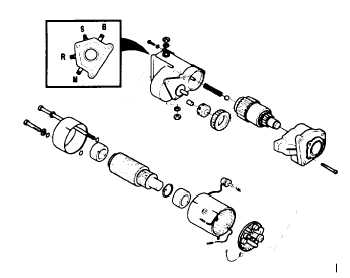

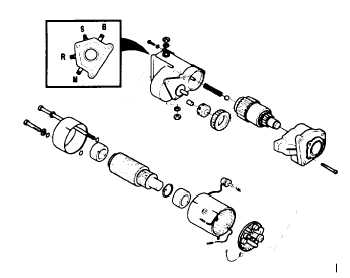

Remove terminal nut on solenoid that connects

motor to solenoid terminal.

2.

Remove the 2 long screws that attach motor to

gear housing.

3.

Remove motor assembly.

4.

Remove 3 Phillips-head screws from solenoid

cap assembly.

5.

Slide out solenoid plunger assembly and plunger

dampener spring.

6.

Position housing so output shaft is in view.

7.

Remove 3 Phillips-head screws which secure

solenoid housing to gear housing.

8.

Remove 2 Phillips-head screws on motor brush-

end.

9.

Remove brushes from brush plate assembly.

10.

Remove armature from frame assembly.

Parts Inspection and Cleaning

NOTE

All bearings are sealed and require no lubrication. Do

not attempt to wash and lubricate bearings. If inspection

reveals a bad bearing, they must be replaced. Replace

bearings by pressing on armature shaft.

1.

Inspect all gears for wear, chipping, or binding.

2.

Inspect

all

bearings

for

wear

and

dirt

contamination. Be sure bearings turn smoothly

without binding. Replace any bearings or gears

which are found to be damaged or worn.

3.

Inspect for damage to gear drive and wear on

armature shaft. Replace armature if gear is

worn.

4.

Inspect commutator. Look for discoloration and

grooves. If grooved, turn commutator on lathe.

5.

Inspect solenoid wiring for dust and dirt. Look for

evidence of overheating. Check insulation for

discoloration and heat damage.

6.

Inspect solenoid contactor ring and solenoid

contactors for excessive wear, dirt, and pitting.

Replace if damaged or worn.

7.

Inspect brushes, brush springs, and shunt wires

for wear and/or damage. Replace, as necessary.

8.

Inspect motor fields for evidence of heat

damage. Check for shorting using a volt-

ohmmeter. Replace, as necessary.

9.

Clean all parts thoroughly prior to reassembly.

F-314

|