| |

TM 10-3930-671-24

b)

Voltage above 9.6 volts. If the voltage stays

above 9.6 volts:

(1)

Be sure all battery connections are clean

and tight.

(2)

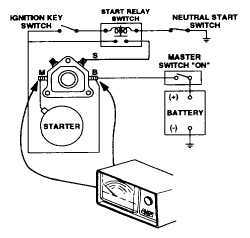

Test the current draw of the starter.

Connect an ammeter and carbon pile

battery load tester in parallel with the

battery terminal of the starter solenoid and

ground

(frame

or

battery

negative

terminal). Be sure that the tester, is

turned OFF.

Clip-on inductance tester may be used.

(3)

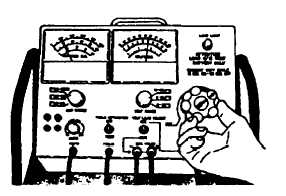

Increase the load (current) until the same

voltage is reached as measured when

cranking the engine. Note the ammeter

reading. Turn OFF the load. The

ammeter reading indicates the cranking

system current draw.

(4)

Compare the measured system draw with

the typical current requirements of the

diesel engine lift truck system.

Typical starter current draw: 180-220 amps.

c)

Low current means high circuit resistance.

Clean connections or replace wiring.

(1)

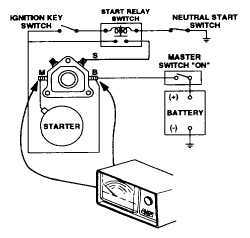

If the current draw is low, measure the

voltage drops in the starter motor circuit

(see Starting System Electrical Checks)

while cranking the engine. Large drops of

over 0.4-1 volt indicate the need to clean

and tighten connections or replace wiring

in that portion of the circuit.

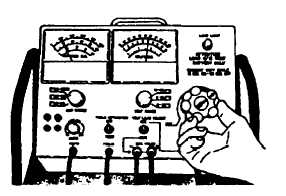

(2)

Use volt-drop test to find source of high

resistance.

d)

High current means high drag resistance.

(1)

If excessive current is observed, then

either a poor engine condition exists, such

as tight rings, tight bearings, or lack of

lubrication, or the starter motor needs to

be removed and repaired. The starter

motor

should

be

checked

for

tight

bearings, pole shoe rubbing, and shorted

or grounded armature or field coils.

(2)

Use torque wrench to measure force

required to turn engine over.

Nothing Happens When Start Attempt Made

1.

If the starter motor won’t crank the engine, it may

be simply a poor electrical contact that is the

problem. Loose or corroded battery connections

can slow down or stop a starter motor. A loose

connection may allow enough current to pass to

operate some electrical accessories but not the

starter motor.

2.

The problem may be either a defective or

discharged battery.

3.

The problem may be an open circuit, loose

connection, or other defect in the starter motor,

solenoid switch, starter relay, neutral start

switch, ignition switch, or the wiring.

4.

The best procedure in diagnosing this type of

starting problem is to systematically check the

possible trouble points, starting with the easiest.

See following procedures.

F-300

|