| |

TM 10-3930-671-24

Battery service must be done by

trained personnel. Battery acid can

cause severe burns and injury.

NOTE

To perform this service procedure, it

is recommended that you first:

•

truck safely.

•

Apply parking brake and block drive

wheels.

•

Return all controls to neutral and turn

ignition key OFF, except as otherwise

noted.

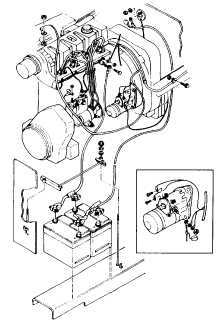

Refer to Section 2. 1, Service Specifications, Section

4.3, Engine Tune- Up, and Section 6.1, Electrical System

Wiring.

Minimum Tools Required

•

Digital voltmeter.

•

Volt-ohm meter.

•

Battery tester.

Remove all jewelry (watch, rings,

bracelets, etc.) before working on

electrical systems. Severe burns can

result from contact with electrical

circuits.

Always

follow

the

manufacturer’s

instructions for the test instrument

being

used

when

making

connections and tests on electrical

circuits or damage to equipment

could occur.

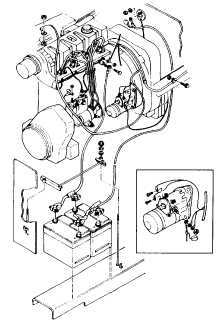

Starting System Mechanical Checks

1.

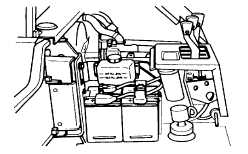

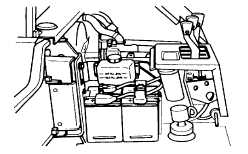

Check the battery.

Be sure that the battery is in good condition and

fully charged before attempting to test the starter

and wiring circuit for problems. It is

recommended that you perform a voltmeter test

and a battery load test.

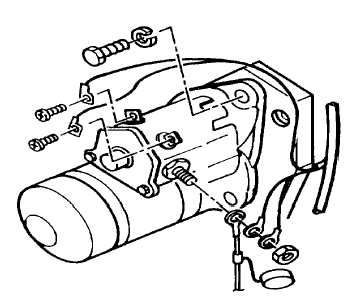

2.

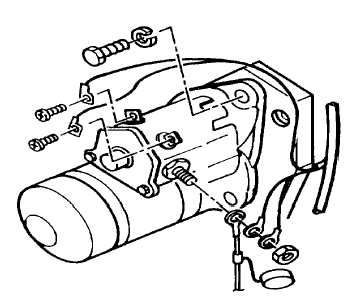

Check starter mounting bolts.

The bolts which mount the starter motor to the

flywheel housing must be kept tightened to the

correct torque. The starter must be held tightly

in the proper mounting position for correct

engagement with the engine flywheel to prevent

damage to both starter pinion and ring gear

teeth, and to provide starter ground circuit.

Refer to Section 2. 1, Service Specifications, for starter

mounting bolt tightening torque.

F-298

|