| |

TM 10-3930-671-24

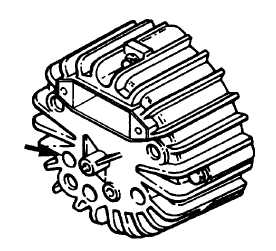

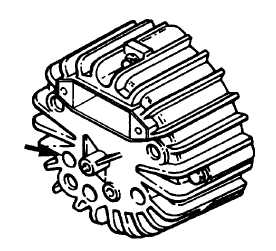

The negative, rectifier diodes, are pressed in the rear

housing (Figure No. 32).

FIGURE NO. 32.

CAUTION

Do

not

attempt

to

substitute

a

replacement diode and solder the

lead to the diode stem. The internal

heat of the alternator may rise to the

point, to soften solder.

The rectifying diode used in the ’TA" alternator have their

leads welded, not soldered, to the stems (Figure No.

33).

FIGURE NO. 33.

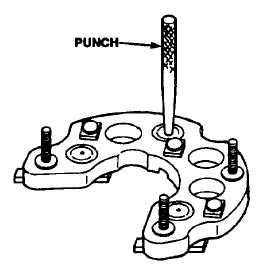

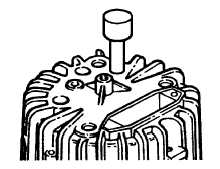

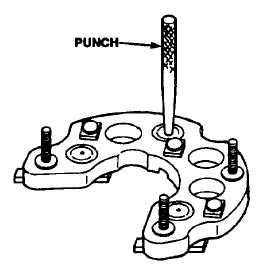

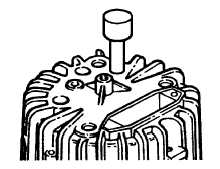

Defective diodes may be pressed out of the heat sink or

the rear housing using regular diode service tools. In

every case, support the underside of the casting involved

to prevent breakage (Figure No’s. 34 & 35).

FIGURE NO. 34.

FIGURE NO. 35.

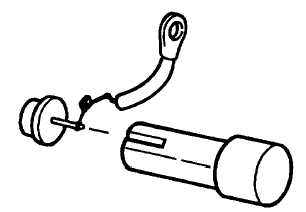

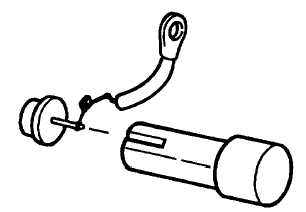

Do not press diodes into same fluted opening of heat

sink, a slight twist will allow new diode to cut its own

opening providing more efficient transfer of heat from the

diode. A typical diode installation tool is shown in (Figure

No. 36).

FIGURE NO. 36.

Replace rear housing or heat sink if either is cracked

while exchanging diodes. Retest diodes after assembly

prior to attaching circuit leads.

F-289

|