| |

TM 10-3930-671-24

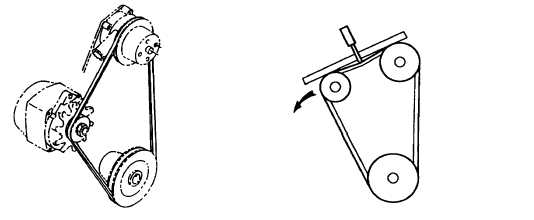

Alternator Installation

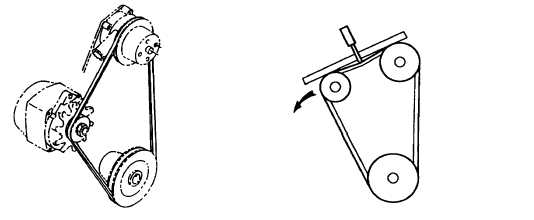

Figure 4. V-Belt Tensioning

Alternator Drive (Fan) Belt

1.

Inspect fan belt and pulleys for damage.

2.

Fan belt must not have any cracks or contact

bottom of pulley grooves.

3.

Be sure there is no oil on fan belt.

4.

Fan belt worn, oily or damaged: Clean or

replace as necessary.

5.

Fan belt adjustment not OK: Adjust as

necessary.

Fan Belt Tensioning

NOTE

Particular attention should be paid to V-belt tension, as

slipping belts are the cause of many other problems in

accessory drives as well as in the charging system. Low

belt tension can induce slipping, with resultant excessive

belt and pulley wear, and overheating of the front

alternator bearing.

A slipping belt will not drive the alternator to full output,

eventually leading to battery discharge problems.

A belt which has been slipping will be glazed and

cracked. Such a belt should be replaced.

Excessive belt tension will create an overload condition

in the alternator front bearing and in water pump

bearings.

Fan Belt Tension Specification

Adjust belt tension to 2.5-3.2 lb-ft. (11.1-14.2 N) .20 in

(5.2 mm) deflection at midpoint of span.

1.

The fan belt is tensioned by adjusting the

alternator.

2.

Loosen bolt at alternator adjusting strap, tighten

belt as required, and retighten bolt.

CAUTION

When tensioning fan belt, tighten

drive belt by applying pressure to the

alternator front housing only. DO

NOT apply pressure to the rear

housing or stator.

NOTE

New belts will lose a substantial

amount of the original tension in the

first few hours of operation as the

belt seats into the pulleys and should

be retensioned accordingly.

F-264

|