| |

TM 10-3930-671-24

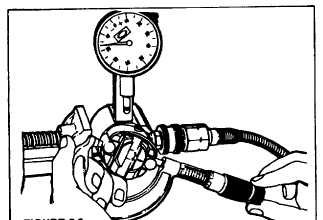

STEP 3 Install roller to roller dimension setting fixture in

a vise (clamping on the flat) so that the air inlet hole is

not covered by the vise. Assemble a 1.4" 18 N.PT. fitting

to the air inlet of the fixture. This fitting should be

adapted to a supply of clean, filtered, compressed air,

regulated to a pressure between 40 and 100 p.s.i.

Handle the rotor carefully, holding the rollers and shoes

in their slots. Install the rotor assembly to the fixture on

the air inlet side. Using a micrometer, measure the roller-

to-roller dimension (Figure 5.3) (distance between the

outer surfaces of the opposed cam rollers) and compare

this with the specification. To set the roller-to roller

dimension to the pump specification, turn the leaf spring

adjusting screw inward (clockwise) to increase and

outward (counterclockwise) to reduce the roller to-roller

dimension.

NOTE

The roller-to-roller setting provides a completely

accurate maximum fuel adjustment and it should not

differ

from

that

shown

in

the

applicable

specification.

FIGURE 5.3.

A centrality check is now required. Refer to specifications

page for allowable tolerances and check as follows:

a. After setting the roller-to-roller dimension to the

amount indicated on the specification, rotate the rotor

until one roller is aligned with the dial indicator plunger.

Slide the indicator inward until the plunger depresses it at

least .010" (.25mm). Lock the indicator retaining screw.

’Zero" the indicator on high point of roller by rotating

knurled dial.

b. Rotate rotor (either direction) until the other roller

depresses the dial indicator plunger.

c. If roller centrality is beyond specified tolerance (see

injection pump specification), roller and/or shoes can be

interchanged. Recheck centrality after each change and

be sure to recheck the roller-to-roller dimension.

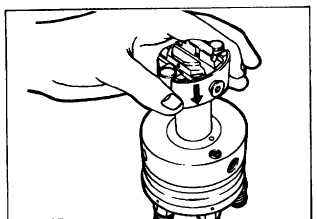

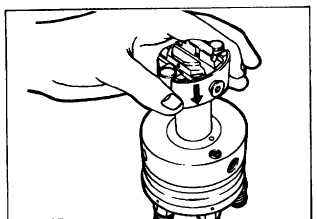

STEP 4 Rinse the hydraulic head assembly in clean

calibrating oil. Remove the rotor assembly from the

fixture, taking care that the shoes and rollers do not

leave their respective slots and rinse in oil. Carefully,

insert the rotor assembly into the hydraulic head (Figure

5.4).

FIGURE 5.4.

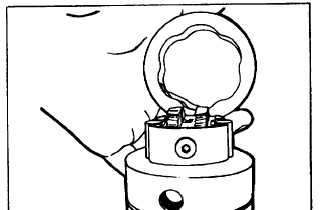

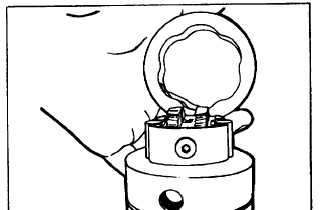

STEP 5 Place the cam ring onto the head and rotor

assembly with directional arrow indicating the direction of

rotation of the pump (Figure 5.5) (Pump rotation is

expressed as viewed from the drive end.). If the cam ring

is installed incorrectly, the pump will not be in time with

the engine.

FIGURE 5.5.

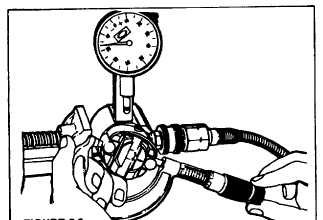

STEP 6 Place the weight retainer assembly on the rotor

(Figure 5.6a).

Make sure the assembly marks on the rotor and the

retainer line up with each other. Assemble the snap ring

to its groove (Figure 5.6b).

F-236

|