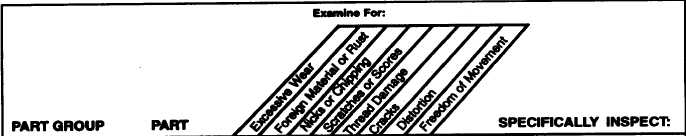

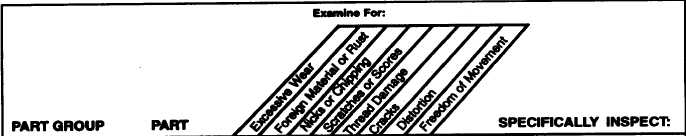

| |

TM 10-3930-671-24

SECTION 4

PARTS INSPECTION

A.

GENERAL INSPECTION

Dirt is the greatest enemy of the fuel injection pump

Keep the work area clean.

Parts must be washed in a suitable solvent and then

placed in a clean pan containing fresh fuel or calibrating

oil.

B.

DETAILED INSPECTION

Examine all parts in accordance with instructions which

follow: Discard flexible retaining ring, all O-rings, seals

and gaskets. Replace with appropriate Roosa Master

gasket kits. Examine all springs for fretting, wear,

distortion or breakage. Clean and carefully check all

bores, grooves and seal seats for damage or wear of any

kind.

Replace damaged or worn parts as necessary.

Housing & Housing

X

X

X

X X

X

X

See Supplementary Inspection 1

Drive

Drive Shaft

X

X

X

X X

X

X

Hydraulic Head Hydraulic Head

X

X

X

X X

X

& Rotor

Vent Wire Assembly

X

X

See Supplementary Inspection 2

Discharge Fittings

X

X

X

X X

X

Inside diameter of discharge fittings,

sealing area for wear, nick & scores

Distributor Rotor

X

X

X X

X

X

X

See Supplementary Inspection 3

Delivery Valve

X

X

X

X

X

X

See Supplementary Inspection 4

Plungers

X

X

X

X

X

See Supplementary Inspection 5

Cam Rollers Shoes

X

X

X

X X

X

See Supplementary Inspection 6

Leaf Spring(s) & Screw(s)

X

X

X

X

X

See Supplementary Inspection 7

Cam

X

X

X

X

X

X

See Supplementary Inspection 8

Governor Weight Retainer X

X

X

X X

Where weights pivot in retainer rocket,

also E ring area for wear, loose pins

Governor Weights

X

X

X

X X

See Supplementary Inspection 9

Governor Thrust Washer

X

X

X

X X

X

Contact areas for excessive wear

Governor Thrust Sleeve

X

X

X

X X

Points of contact with governor arm for

excessive wear

Transfer

End Cap

X

X

X

X

Pump

Inlet Screen

X

X

X

Screen and soldered area for breakage

End Plate Adi. Plug

X

X

Tighten es in regulator, plugged orifice,

loose plate

Regulating Piston

X

X

X

X X

Regulator

X

X

X

X X

X

Inside diameter of regulator

Blades

X

X

X

X X

See Supplementary Inspection 10

Liner

X

X

X

X

Inside diameter in high-pressure area for

wear

Rotor Retainers

X

X

X

X

Governor

Pivot Shaft

X

X

X

X

X

Chipped or worn knife edge

Arm

X

X

X

X

X

X

Points of contact with sleeve & pivot

alt for extreme wear

Metering Valve

X

X

X

X X

X

Contact area body for excessive wear

Metering Valve Arm

X

X

X

X

X

X

Inspect pin for wear or looseness

Linkage

Linkage Hook

X

X

X

X X

X

X

X

Metering valve pin hole

Advance

Piston

X

X

X

X

X

Cam Advance Screw

X

X

X

X X

X

X

Plugs

X

X

X

X X

X

X

X

Bore for excessive wear

Head Locating Screw

X

X

X X

X

Orifice

F-232

|