| |

TM 10-3930-671-24

SECTION 3 DISASSEMBLY

Study the manual first. Before commencing disassembly

of the pump, cover inlet and outlet holes, remove all

external grease and dirt by washing the unit with diesel

fuel and blowing it off with filtered compressed air. It

must be constantly kept in mind that dirt, dust and

foreign matter are the greatest enemies of the fuel

injection pump. As an added precaution to prevent dirt

from entering the fuel system while servicing the pump, it

is essential that a clean work space, clean tools and

clean hands be used.

NOTE

All seals and gaskets should be discarded during

disassembly. A clean pan should be available in

which the parts may be placed during disassembly,

and a pan of clean diesel fuel or calibrating oil must

be available in which the parts may be flushed. It is

recommended that these be deep pans with rounded

comers to lessen the chances of dirt pockets.

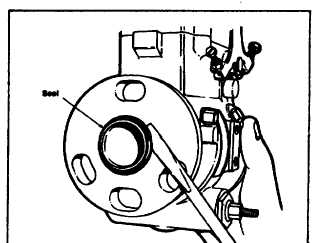

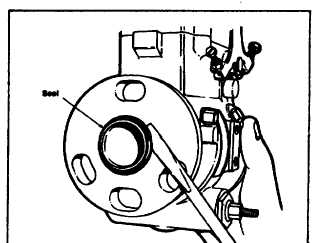

STEP 1 Remove the pilot tube seal (Figure 3.1).

FIGURE 3.1

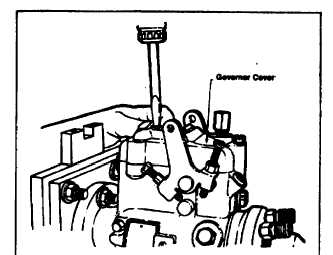

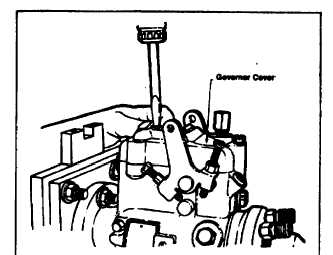

STEP 2 Mount the pump in a holding fixture. Always use

a fixture to avoid pump sliding out and becoming

damaged, never clamp the pump in a vise. Remove all

lead plumb sealing wires. Unscrew the three cover

holddown screws (Figure 3.2a).

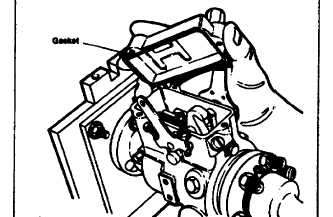

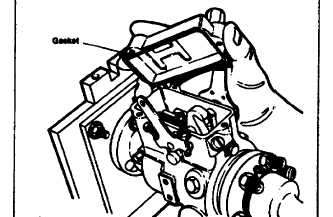

Remove the governor control cover and cover gasket

(Figure 3.2b).

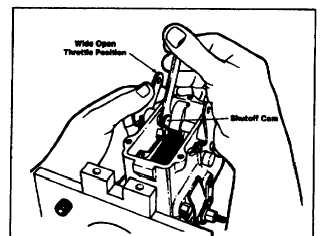

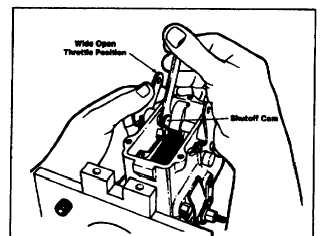

STEP 3 Remove the shutoff cam by rotating the shutoff

lever to the wide open throttle (WOT) position. Place

shutoff cam remover, with tab beneath the shorter leg

FIGURE 3.2a.

FIGURE 3.2b.

of the shutoff cam, on the shutoff shaft and pry gently,

sliding the cam off the shaft assembly (Figure 3.3).

Discard the shutoff cam.

NOTE

Do not reuse this shutoff cam, use new cam.

FIGURE 3.3.

F-223

|