| |

TM 10-3930-671-24

due to the cam rollers passing the highest point on the

cam lobe.

Following this, the rotor discharge port closes completely

and a residual injection line pressure is maintained. Note

that the delivery valve is only required to seal while the

discharge port is opened. Once the port is closed,

residual line pressures are maintained by the seal of the

close fitting head and rotor.

G.

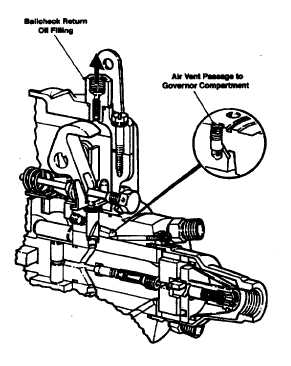

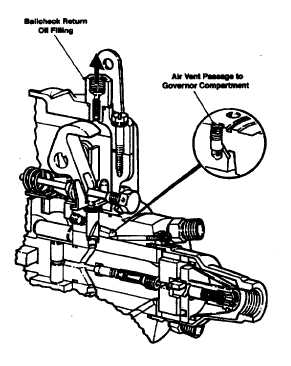

RETURN OIL CIRCUIT

Fuel under transfer pump pressure is discharged into a

vent passage in the hydraulic head (Figure 1.10). Flow

through the passage is restricted by a vent wire

assembly to prevent excessive return oil and undue

pressure loss. The amount of return oil is controlled by

the size of wire used in the vent wire assembly, i.e. the

smaller the wire the greater the flow and vice versa. The

vent wire assembly is available in several sizes in order

to meet the return oil quantities called for on the

specification. Note that this assembly is accessible by

removing only the governor cover. The vent passage is

located behind the metering valve bore and connects

with a short vertical passage containing the vent wire

assembly and leads to the governor compartment.

Should a small quantity of air enter the transfer pump, it

immediately passes to the vent passage as shown. Air

and a small quantity of fuel then flow from the housing to

the fuel tank and via the return line.

Housing pressure is maintained by a spring-loaded

ballcheck return fitting in the governor cover of the pump.

H.

MECHANICAL ALL SPEED GOVERNOR

The governor serves the purpose of maintaining the

desired engine speed within the operating range under

various load settings.

In the mechanical governor (Figure 1.11), the movement

of the weights acting against the governor thrust sleeve

rotates the metering valve by means of the governor arm

and linkage hook. This rotation varies the registry of the

metering valve opening to the passage from the transfer

pump, thereby controlling the quantity of fuel to the

plungers. The governor derives its energy from weights

pivoting in the weight retainer. Centrifugal force tips

them outward, moving the governor thrust sleeve against

the governor arm, which pivots on the knife edge of the

pivot shaft and, through a simple, positive linkage,

rotates the metering valve. The force of the weights

against the governor arm is balanced by the governor

spring force, which is controlled by the manually

positioned throttle lever and vehicle linkage for the

desired engine speed.

In the event of a speed increase due to a load reduction,

the resultant increase in centrifugal force of the weights

rotates the metering valve clockwise to reduce fuel. This

limits the speed increase (within the operating range) to

a value determined by governor spring rate and setting of

the throttle.

When the load on the engine is increased, the speed

tends to reduce. The lower speed reduces the force

generated by the weights permitting the spring force to

rotate the metering valve in the counterclockwise

direction to increase fuel. The speed of the engine at any

point within the operating range is dependent upon the

combination of load on the engine and the governor

spring rate and setting as established by the throttle

position. A light idle spring is provided for more sensitive

regulation when weight energy is low in the low end of

speed range. The limits of throttle travel are set by

adjusting screws for proper low idle and high idle

positions.

A light tension spring on the linkage assembly takes up

any slack in the linkage joints and also allows the shutoff

mechanism to close the metering valve without having to

overcome the governor springing force. Only a very light

force is required to rotate the metering valve to the

closed position.

FIGURE 1.10.

F-220

|