| |

TM 10-3930-671-24

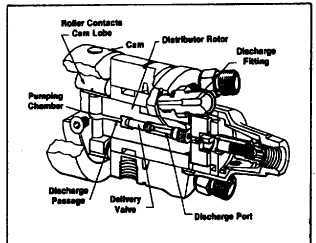

The plungers move outward a distance proportionate to

the amount of fuel required for injection on the following

stroke. If only a small quantity of fuel is admitted into the

pumping chamber, as at idling, the plungers move out a

short

distance.

Maximum

plunger

travel

and,

consequently, maximum fuel delivery are limited by the

leaf spring which contacts the edge of the roller shoes.

Only when the engine is operating at full load will the

plungers move to the most outward position. Note that

while the angled inlet passages in the rotor are in registry

with the ports in the circular charging passage, the rotor

discharge port is not in registry with a head outlet (Figure

1.7). Note also that the rollers are off the cam lobes.

Compare their relative positions (Figures 1.7 and 1.8).

Discharge Cycle

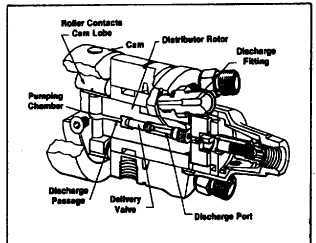

As the rotor continues to revolve (Figure 1.8), the inlet

passages move out of registry with the charging ports.

The rotor discharge port opens to one of the head

outlets. The rollers then contact the cam lobes forcing

the shoes in against the plungers and high-pressure

pumping begins.

Beginning of injection varies according to load (volume of

charging fuel), even though rollers may always strike the

cam at the same position. Further rotation of the rotor

moves the rollers up the cam lobe ramps pushing the

plungers inward. During the discharge stroke, the fuel

trapped between the plungers flows through the axial

passage of the rotor and discharge port to the injection

line. Delivery to the injection line continues until the

rollers pass the innermost point on the cam lobe and

begin to move outward. The pressure in the axial

passage is then reduced, allowing the nozzle to close.

This is the end of delivery.

F.

DELIVERY VALVE

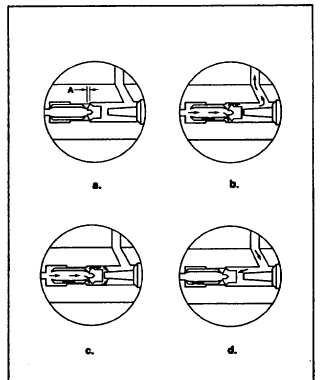

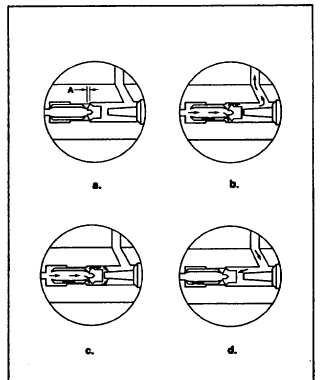

The delivery valve (Figures 1.9a through 1.9d) rapidly

decreases injection line pressure after injection to a

predetermined value lower than that of the nozzle closing

pressure. This reduction in pressure permits the nozzle

valve to return rapidly to its seat, achieving sharp delivery

cutoff and preventing improperly atomized fuel from

entering the combustion chamber.

FIGURE 1.9.

The delivery valve operates in a bore in the center of the

distributor rotor. Note that the valve requires no seat only

a stop to limit travel. Sealing is accomplished by the

close clearance between the valve and bore into which it

fits. Since the same delivery valve performs the function

of retraction for each injection line, the result is a smooth

running engine at all loads and speeds.

When injection starts, fuel pressure moves the delivery

valve slightly out of its bore and adds the volume of its

displacement, section "A," to the delivery valve spring

chamber. Since the discharge port is already opened to a

head

outlet,

the

retraction

volume

and

plunger

displacement volume are delivered under high pressure

to the nozzle. Delivery ends when the pressure on the

plunger side of the delivery valve is quickly reduced.

FIGURE 1.8.

F-219

|