| |

TM 10-3930-671-24

FIGURE 1.4.

D.

TRANSFER PUMP

The positive-displacement, vane-type fuel transfer pump

consists of a stationary liner and spring-loaded blades

which are carried in slots in the rotor. Since the inside

diameter of the liner is eccentric to the rotor axis, rotation

causes the blades to move in the rotor slots.

This blade movement changes the volume between the

blade segments.

Transfer pump output volume and pressure increases as

pump

speed

increases.

Since

displacement

and

pressure of the transfer pump can exceed injection

requirements, some of the fuel is recirculated by means

of the transfer pump regulator to the inlet side of the

transfer pump.

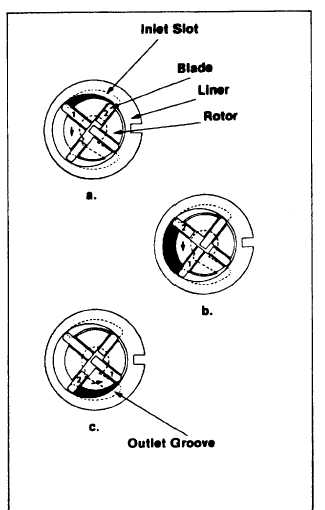

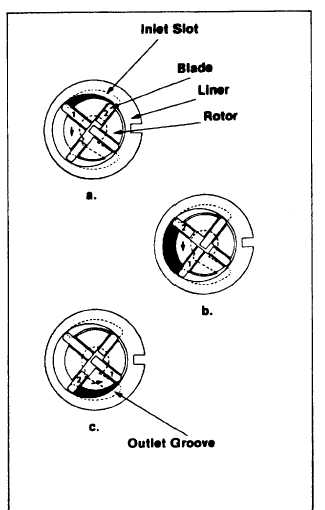

Figure 1.5 illustrates the pumping principle. Radial

movement causes a volume increase in the quadrant

between blades 1 and 2 (Figure 1.5a). In this position,

the quadrant is in registry with a kidney-shaped inlet slot

in the top portion of the regulator assembly. The

increasing volume causes fuel to be pulled through the

inlet fitting and filter screen into the transfer pump liner.

Volume between the two blades continues to increase

until blade 2 passes out of registry with the regulator slot.

At this point, the rotor has reached a position where

outward movement of blades 1 and 2 is negligible and

volume is not changing (Figure 1.5b). The fuel between

the blades is being carried to the bottom of the transfer

pump liner.

As blade 1 passes the edge of the kidney-shaped groove

in

the

lower

portion

of

the

regulator

assembly

(Figure 1.5c), the liner, whose inside diameter is

eccentric to the rotor, compresses blades 1 and 2 in an

inward direction (Figure 1.5a). The volume between the

blades is reduced and pressurized fuel is delivered

through the groove of the regulator assembly, through

the transfer pump, through the rotor, past the rotor

retainers and into a channel on the rotor leading to the

hydraulic head passages. Volume between blades

continues to decrease, pressurizing the fuel in the

quadrant, until blade 2 passes the groove in the regulator

assembly.

FIGURE 1.5.

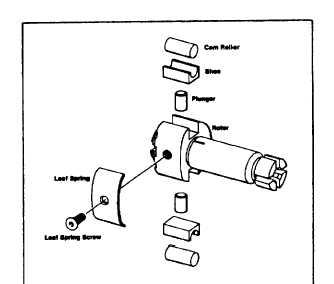

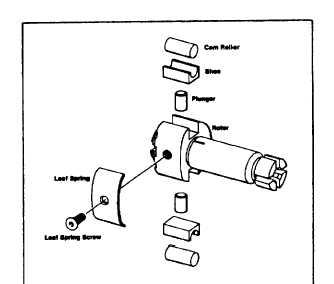

REGULATOR ASSEMBLY OPERATION

Figure

1.6

shows

the

operation

of

the

pressure

regulating piston while the pump is running. Fuel output

from the discharge side of the transfer pump forces the

piston in the regulator against the regulating spring. As

flow increases, the regulating spring is compressed until

the edge of the regulating piston starts to uncover the

pressure regulating slot "S" (Figure 1.6b). Since fuel

F-217

|