| |

TM 10-3930-671-24

The DB2 pump contains its own mechanical governor

capable of close speed regulation. The centrifugal force

of the weights in their retainer is transmitted through a

sleeve to the governor arm and through a positive

linkage to the metering valve. The metering valve can

be closed to shut off fuel through a solid linkage by an

independently operated shutoff lever, or by an electrical

solenoid.

The automatic advance is a hydraulic mechanism which

advances or retards the pumping cycle.

B.

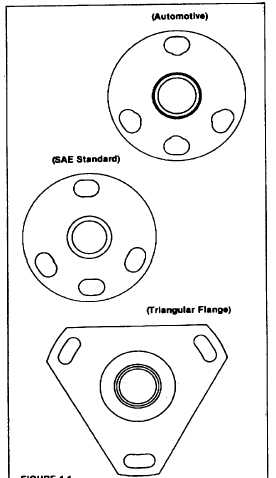

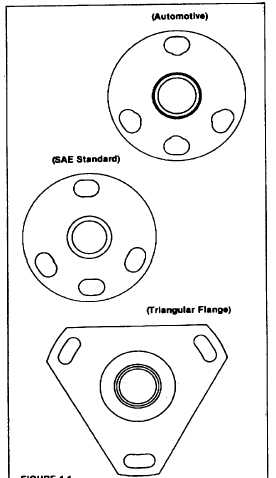

MOUNTING FLANGES

FIGURE 1.1

Shown above are the typical DB2 mounting flange

configurations. These are the three most common

types. Note that the automotive flange has scalloped

slots to enable it to be mounted on a standard pump

holding fixture.

C.

FUEL FLOW

The operating principles of the pump can be understood

more readily by following the fuel circuit during a

complete pump cycle cutaway, (Figure 1.2) and fuel flow

schematic (Figure 1.3). Also, see exploded view of the

rotor assembly (Figure 1.4).

Fuel is drawn from the supply tank through filters into the

pump inlet through the inlet filter screen (1) by the vane-

type fuel transfer pump (2). Some fuel is bypassed

through the pressure regulator assembly (3) to the

suction side.

Fuel under transfer pump pressure flows through the

center of the transfer pump rotor, past the rotor retainers

(4) into a circular groove on the rotor. It then flows

through a connecting passage (5) in the head to the

automatic advance (6), up through a radial passage (7)

and then through a connecting passage (8) to the

metering valve. The radial position of the metering

valve, controlled by the governor, regulates flow of the

fuel into the radial

charging

passage

(9)

which

incorporates the head charging ports.

As the rotor revolves, the two rotor inlet passages (10)

register with the charging ports in the hydraulic head,

allowing fuel to flow into the pumping chamber. With

further rotation, the inlet passages move out of registry

and the discharge port of the rotor registers with one of

the head outlets. While the discharge port is opened, the

rollers (11) contact the cam lobes forcing the plungers

together. Fuel trapped between the plungers is then

pressurized

and

delivered

by

the

nozzle

to

the

combustion chamber.

Self-lubrication of the pump is an inherent feature of the

Roosa Master design. As fuel at transfer pump pressure

reaches the charging ports, slots on the rotor shank

allow fuel and any entrapped air to flow into the pump

housing cavity.

In addition, an air vent passage (12) in the hydraulic

head connects the outlet side of the transfer pump with

the pump housing. This allows air and some fuel to be

bled back to the fuel tank via the return line. The fuel

thus bypassed fills the housing, lubricates the internal

components, cools and carries off any small air bubbles.

The pump operates with the housing completely full of

fuel; there are no dead air spaces anywhere within the

pump.

F-215

|