| |

TM 10-3930-671-24

Installing & Timing

A New Fuel Injection Pump

WARNING

Bodily Injury may result during the timing

operation of the fuel injection pump n the engine

is running. Do not attempt to adjust the timing

without the pump mounting bolts securely

torqued.

NOTE

To obtain access to the Internal timing marks,

the original manufacturer’s sell will have to be

broken. These sea is should therefore be

removed only by authorized personnel who must

reseal when the adapter plate or cover is

replaced. Otherwise, the warranty may become

void.

1.

Repeat preceding Steps 1 thru 11 of Reinstalling

& Timing the Original Fuel Injection Pump.

2.

Rotate

crankshaft

until

#1

piston

is

on

compression stroke and timing mark 13°-150

BTDC lines up with the pointer in bell housing or

crankshaft pulley.

NOTE

Be sure that #1 piston is on compression stroke

by turning both push rods by hand, Indicating

both valves are closed.

3.

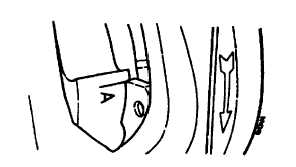

Remove inspection plate on the injection pump

housing. Turn pump until Line "A" on the drive shaft

lines up with the flat end of the circlip.

4.

Tighten pump mounting bolts.

5.

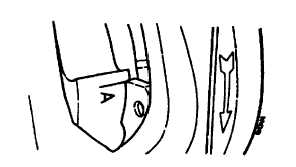

Rotate

crankshaft

approximately

500

counterclock-wise. Then rotate clockwise,

stopping at 13°- 150 BTDC. Recheck that Line

'A" is still in line with flat end of circlip. If not,

reset.

6.

Replace inspection plate on the injection pump.

7.

Repeat preceding Steps 14 thru 17.

8.

Restamp the pump to adapter scribe marks.

Fuel Recommendations

Diesel fuel selection, handling, and filtration Is of great

importance. The fuel not only supplies the energy for all

the work done by the engine, it also lubricates the parts

of the fuel injection system which operate with very close

tolerances. Fuel that contains water, abrasives, or

sulphur in excess of the recommended specifications

can cause extensive damage to the injection pump and

engine.

Diesel Fuel Specifications

TMD27 diesel engines have been designed and

developed to use No. 1-D (light fuel) and preferably No.

2 (heavy fuel), which can be a cracked residual, a blend

of

preferably

a

straight-run

distillate

having

characteristics including the following selected items:

Cetane Number ......................... 50 desired, 45 minimum

Water and Sediment ............. 0.05% maximum by weight

Total Sulphur ........................................... 0.5% maximum

F-208

|