| |

TM 10-3930-671-24

Under normal operation or during routine maintenance it

will probably not be necessary to time the injection pump.

However, i the pump is removed or a new pump

installed, it must be timed according to the following

procedures.

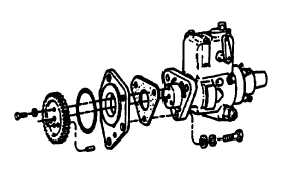

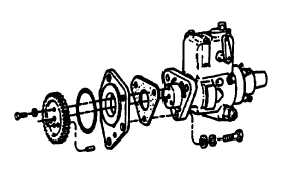

Reinstalling & Timing the

Original Fuel Injection Pump

WARNING

Bodily Injury may result during the

timing operation of the fuel injection

pump n the engine Is running. Do not

attempt to adjust the timing without

the pump mounting bolts securely

torqued.

1.

Install new gasket on the pump face and install

pump on the pump adapter plate.

2.

Install adapter plate mounting bolts finger tight.

3.

Install the alignment dowel through gear into the

pump drive shaft.

NOTE

The remaining hole in the pump gear is for timing the

pump to the engine.

4.

Mount the drive gear to the pump drive shaft

using three (3) screws and washers. Tighten

screws to 20-25 lb ft [27-34 N•m] torque.

5.

Install new 0-ring on hub of the pump adapter

plate.

6.

Turn engine crankshaft until #1 cylinder is at

TDC on compression stroke with beveled gear

tooth on the driver gear (mounted behind cam

gear) approximately centered in hole in rear of

gear case.

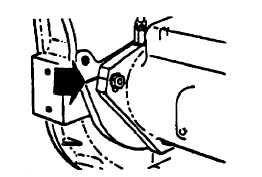

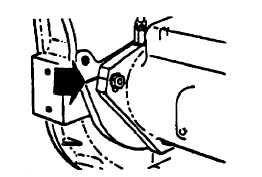

7.

Remove screw plug in front cover of gear case.

This is for the purpose of installing a timing pin.

Use a 15/64" drill as a timing pin.

8.

Install fuel injection pump and adapter. Turn

pump and pump gear until pump can be installed

with the timing pin (15/64" drill) passing through

the hole in the pump gear.

9.

Rotate the pump adapter plate and align scribe

marks.

10.

Install and tighten adapter mounting bolts and

screws.

11.

Remove the timing pin (15/64" drill) and replace

the screw plug and washer.

12.

Rotate the injection pump to align the scribe

mark on the pump flange and on the pump

adapter plate.

13.

Tighten pump mounting bolts.

14.

Attach high-and low-pressure fuel lines and

hoses.

15.

Attach wire to cut-off solenoid.

16.

Connect throttle control linkage.

17.

Check Operation

NOTE

It is strongly recommended that a

diesel Injection timing light be used

to check Injection timing.

a)

Start engine.

b)

Run engine at 1600 rpm idle.

c)

Check pump timing. Dynamic timing should

be 13°-15° BTDC @ 1600 rpm, no-load.

F-207

|