| |

TM 10-3930-671-24

3.

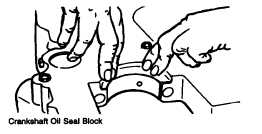

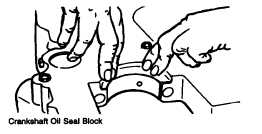

Apply a light coat of cement (national oil seal or

EC-847) to the butting ends of the crankshaft oil

seal halves. Allow to become tacky before

assembling. Lightly coat the crankshaft contact

edge of the seal with graphite grease to prevent

damage prior to use.

4.

Install crankshaft.

5.

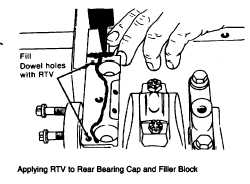

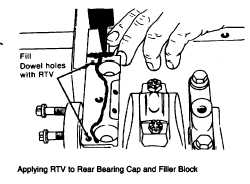

Apply a light coating of RTV gasket material to

surface "B" and graphite grease to the oil seal

lip. Carefully install the combination rear bearing

cap and filler block on to the dowels. Insert the

capscrews and torque to 150-162 N•m (110-120

Lb. Ft.)

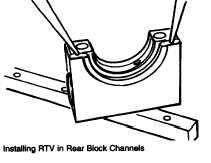

6.

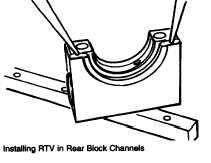

After the rear cap is in place and torqued, inject

RTV into each side seal slot "D" as shown in

illustration. Force the RTV into the channels

until a steady flow comes out the corner

chamfers.

NOTE

0il leakage will occur if any voids are

left along these slots.

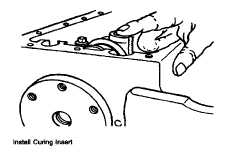

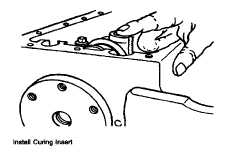

7.

Dip the curing insert in clean water. Install

curing insert until approximately 5/8" protrudes

from slot. Cut off flush with pan rail. This insert

insures complete cure of the RTV.

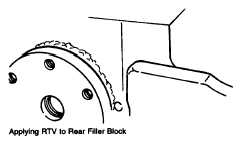

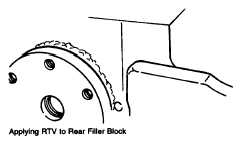

8.

Prior to installing oil pan, apply a small bead of

RTV material to the rear bearing cap and filler

block as shown.

OIL PUMP

The oil pump is assembled to the front of the cylinder

block and front main bearing cap and is held in place by

capscrews.

The pump is driven by a hardened key mounted in the

crankshaft.

F-182

|