| |

TM 10-3930-671-24

CAUTION

When Installing camshaft, use special

care to prevent camshaft bumping

and loosening expansion plug at rear

of crankcase causing an oil leak.

1.

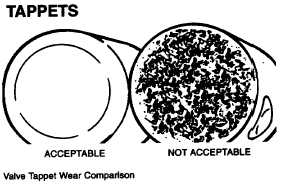

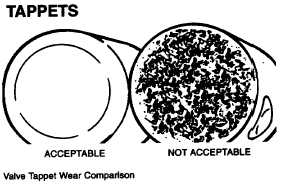

Inspect each tappet carefully. Two or three

small pits on the contact face is acceptable;

more than that calls for replacement of the

tappet. A damaged tappet could mean possible

damage to the camshaft.

2.

Check the outside diameter with a micrometer to

determine if replacement is necessary because

of wear. Refer to limits and clearance section.

REAR CRANKSHAFT OIL SEALS

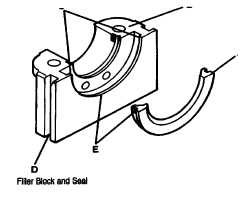

The overhead valve engines have the rear crankshaft oil

seals incorporated in the combination rear main bearing

cap and filler block.

The rear crankshaft oil seal has a stiffener ring imbedded

in the rubber and no metal retainer is required.

The overhead valve engines have a good, trouble-free

rear crankshaft oil seal if carefully installed.

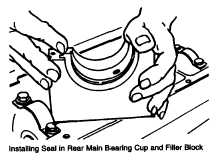

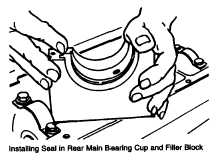

IMPORTANT: Installing rear oil seals correctly

demands careful workmanship. Install seal with lip

pointing toward engine.

Worn oil seals should be replaced in the following

manner:

1.

Remove rear bearing cap and filler block

assembly by using a puller.

Remove old seals and thoroughly clean all contact

surfaces.

2.

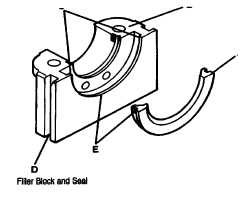

Install crankshaft oil seals "A" on engine block

and main bearing cap.

Before installing break edge ’C" slightly on both cap and

block to avoid cutting the seals during installation and

coat seal edge ’E", contacting the groove with sealing

compound.

NOTE

This oil seal can be Installed without

removing the crankshaft in this case,

use only light grease in the seal

groove to assist sliding the seal in

place. Apply pressure to the seal so

that it will hug the crankshaft which

will also help moving it In place.

F-181

|