| |

TM 10-3930-671-24

BEARINGS

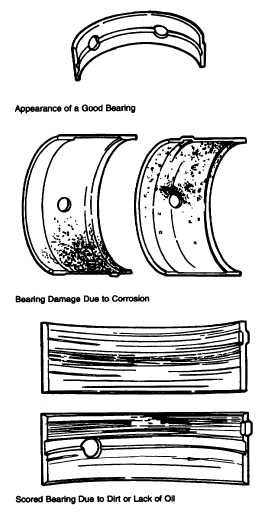

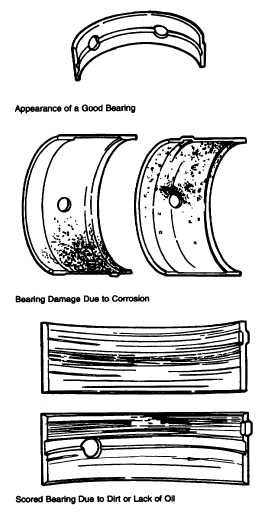

Tri-metal bearings when new are smooth and highly

polished. However, a very few hours of operation will

change their appearance completely. The bearing

surface becomes a leaden gray in color and develops

minute craters, almost cellular in appearance. This

appearance is a natural characteristic of this type of

bearing and in no way indicates failure.

7.

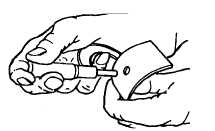

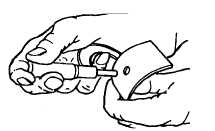

If the visual inspection appears satisfactory, they

should be removed and checked for thickness

using a ball micrometer.

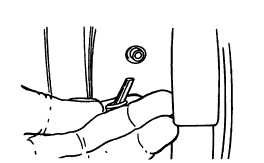

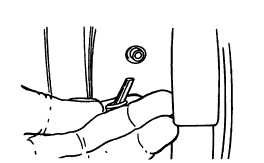

To remove the upper half of the bearing shell use a

special tool obtainable at most parts houses, which is a

pin with an angular head. It may be inserted in the oil

hole of the crankshaft and as the crankshaft is turned in

a clockwise direction, the head of this pin picks up the

bearing shell and forces it out of the bore in the block.

The thickness of the bearing shells is given in the Limits

and Clearance Chart, and if this thickness has been

reduced more than 0.013mm (.0005’) beyond the

maximum allowable tolerance the bearing shell must be

replaced.

CAUTION

The upper main bearing shells are

grooved. The lower main bearing

shells on some models, are not. The

ungrooved bearing shell must be

placed in the bearing cap, not In the

block, or oil to the bearing will be cut

off and damage to engine will result.

8.

If visual inspection of the crankshaft shows no

indication of excessive wear or scoring, the

clearance of the bearing should be checked.

F-179

|