| |

TM 10-3930-671-24

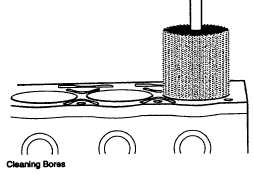

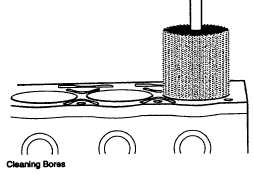

After all honing operations are complete, thoroughly

wash the bores with soap, hot water, and a stiff brush to

remove all traces of grit. Kerosene or other solvents will

not remove the grit. Rinse the block with clean, clear

water and dry with compressed air.

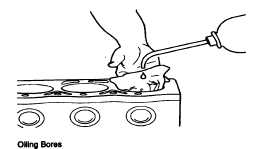

When you have finished cleaning the block, run a clean,

dry paper towel through the bores. The paper towel

should come out clean.

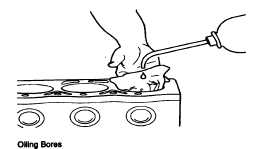

If not, the bores must be rewashed. As soon as the

bores have dried, lubricate with engine oil immediately to

prevent rust. This completes the honing operation.

PISTONS

Check the pistons for excessive ring groove wear, and

replace any that exceed the allowable limits in our Limits

and Clearance Data.

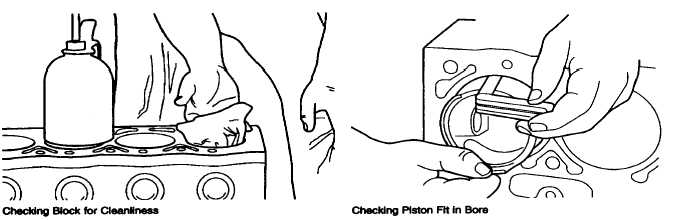

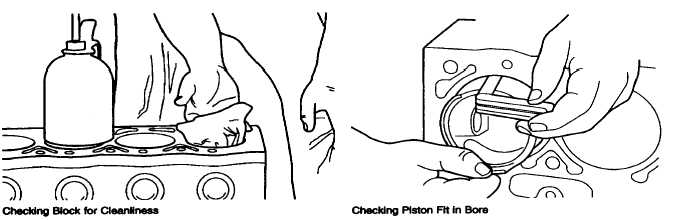

The cylinder walls and pistons must be perfectly clean

and dry when fitting pistons in the cylinder bores.

Pistons should be fitted with the block and piston at room

temperature 68°to 70°F(20°C 21°C).

PISTON FIT ON STANDARD PISTONS (with 5 to 10 lbs

(2.3 to 4.5 kg) Pull) TMD series .003" (0.08mm)

Check the piston fit in the bore using a half-inch wide

strip of feeler stock (of the thickness specified in the

Limits and Clearance Chart) the feeler being attached to

a small scale of approximately 15 lbs (7 kg) capacity.

F-175

|