| |

TM 10-3930-671-24

Section 8 - Engine Repair & Overhaul

This section includes instructions for repairs and

overhaul of the component units of Continental industrial

diesel engines.

Provide a clean place to work and clean the engine

exterior before you start disassembling-dirt causes

engine failures.

Many shop tools have been developed to save time and

assure good workmanship; these should be included in

your equipment.

Use only genuine Continental parts in Continental

engines since years of development and testing have

gone into these specifications to assure maximum life

and performance.

CYLINDER HEAD

The cylinder head is the most important part of the

engine

assembly

since

it

contains

the

complete

combustion chamber including valves, fuel injection

nozzles, glow plugs, and cored passages for air, exhaust

and water flow.

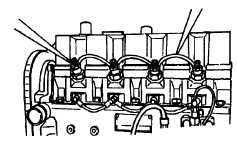

Removing the Cylinder Head

1.

Drain water from engine and disconnect radiator

or heat exchanger hoses.

2.

Remove cylinder head cover by removing the

cap screws holding the cover to the cylinder

head.

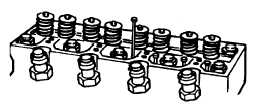

3.

Remove rocker arm shaft assembly and push

rods. Grip the push rods and snap them

sideways out of the tappet sockets as shown in

the illustration. This method serves to break the

hydraulic connection and permits lifting the push

rods out and leaving the tappets in place.

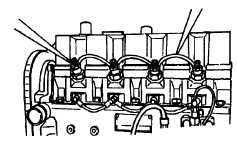

4.

Disconnect the injectors and leak-off lines at

both the nozzle and pump connections.

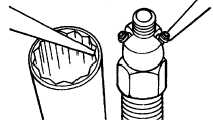

Removing Push Rod from Ball Socket of Tappet

Socket Relief Clearance

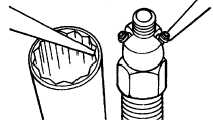

Caution should be used when replacing the fuel injectors

to prevent loosening the injector leak-off nipples.

Be sure to cut a relief in the inside of your socket for

clearance. This will prevent an interference between the

socket and the leak-off nipple.

Disconnecting Injector Leak-off Line

CAUTION

Always

cover

openings

with

protective caps at any time when

lines are disconnected. This will

prevent any dirt or foreign matter

from entering.

5.

Remove injection nozzle assemblies. Place a

protective cap over ends of injector for keeping

openings clean. Refer to fuel injection system

for testing procedures.

F-167

|