| |

TM 10-3930-671-24

9.

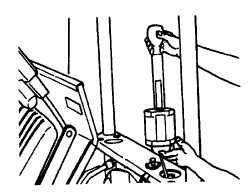

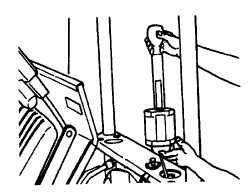

Use a coolant tester to test the low temperature

protection ("freeze") level (proportion of ethylene

glycol to water) of the coolant solution. Add

coolant solution (antifreeze and/or water) to

provide maximum cooling system protection

(50/50 mixture).

Cooling System Pressure Tests

If the need is indicated for further maintenance and

testing of the cooling system, check for both external and

internal leaks in the cooling system with an accurate

pressure pump and gauge tester.

Cooling System Pressure (radiator cap): 14 psi (12-

16psi)

Refer to Section 2.1, Service Specifications, Cooling

System.

Radiator & Cooling System

1.

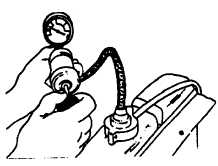

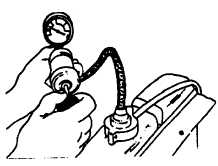

Pressure test the radiator cap to determine if it is

holding the correct pressure. Wash cap in clean

water to remove dirt or scale from sealing

surfaces. Wet rubber sealing surfaces and

install cap tightly on the tester. Pressurize tester

and radiator cap.

2.

The gauge pressure reading should be within the

specified limits of the cap relief pressure. If the

test relief pressure either exceeds or is below

the specified limits, replace cap.

Radiator Cap

1.

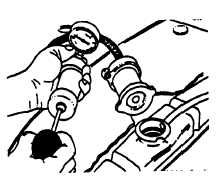

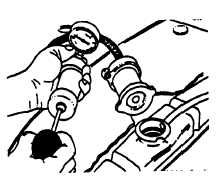

Pressure test the radiator and cooling system to

determine if it will hold the correct pressure

without leaks or failure. Wet the rubber sealing

surfaces and install the tester cap tightly on the

radiator filler neck. Apply pressure to the cooling

system equal to the radiator cap specified relief

pressure.

2.

Observe gauge reading for approximately 2

minutes. Pressure should not drop during this

time. If pressure drops, check for leaks in

radiator,

radiator

cap,

hoses,

connections,

engine components, etc.

Thermostat

1.

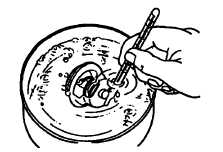

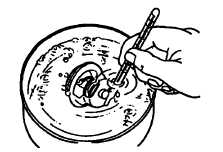

Remove and test the engine thermostat to

determine if it closes correctly and opens at the

specified temperature.

2.

Place thermostat fully immersed in a pan of

water. Heat the pan slowly while stirring water to

produce

an

even

temperature.

Use

a

thermometer to measure the temperature at

which the thermostat valve cracks (starts to

open) and, when it is fully open, measure the

valve lift distance of the fully opened valve. If

test results are not to specification, replace

thermostat.

3.

Replace the thermostat if even a slight opening

of the valve at normal temperature is found or if

its appearance shows any breakage. If the

sensing part is damaged, the thermostat valve

will remain closed.

F-96

|