| |

TM 10-3930-671-24

4.

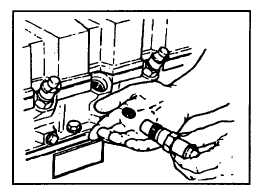

Clean the injector bore and crank the engine to

blowout any loose carbon particles.

5.

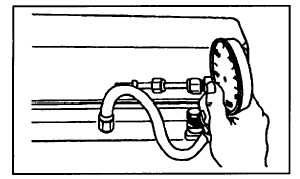

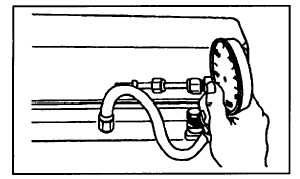

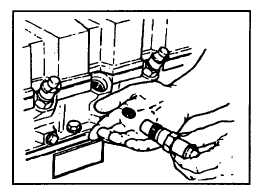

Install high-range compression gauge with the

appropriate adapters, as necessary. A new seat

washer should be used.

Injector Thread: M24 x 2

6.

Connect the compression test gauge.

7.

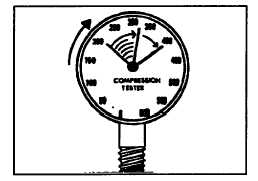

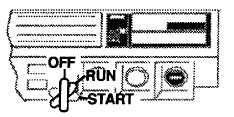

Crank the engine for 5 compression strokes or

until the reading stops increasing.

8.

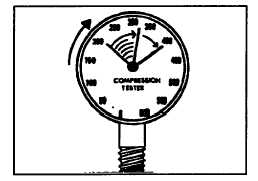

Observe

and

record

the

readings

for

all

cylinders.

Analysis of Diesel Compression Pressure Readings

1.

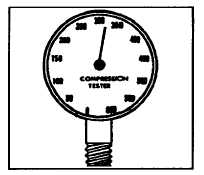

All cylinders should read between 325 - 400 psi

@ 150 rpm.

1)

A low, even compression in two adjacent

cylinders indicates a cylinder head gasket

leak.

2)

A reading of 20 psi above the other

cylinders indicates high carbon deposits

on the piston and cylinder head.

3)

A reading of more than 20 psi below the

other cylinders indicates leakage at the

cylinder head gasket, valves, or piston

rings.

2.

To determine if the rings or valves are at fault,

perform a static leak-down test. Follow the

instructions that are provided in your leak-down

test equipment.

Test Completion

1.

Install the injectors.

NOTE

When installing injectors in the engine cylinder head, it is

essential that a new, correct type heat-shield washer be

fitted between the nozzle cap and the cylinder head.

2.

Tighten injectors evenly to torque specification:

52 Ib-ft (70 N•m).

F-84

|